RFID Laundry Tag Guide 2025: Smarter Tracking, Less Waste, and Real Results

विषयसूची

परिचय

A recent study by the RFID Journal found that businesses using RFID in laundry saw up to 30% improvements in operational efficiency. [Source: RFID Journal]

In this guide, I’ll explain RFID laundry tags, how they work, and how they can save you time and money. If you still rely on manual tracking or barcodes, this could be your next big upgrade.

What is an RFID laundry tag?

RFID stands for Radio Frequency Identification. An RFID laundry tag is a small, durable chip embedded in or sewn onto laundry items like linens, uniforms, and towels. These RFID tags for uniforms store a unique ID number that can be read using radio waves. When scanned by a reader, the system instantly recognizes the item, logs its activity, and updates the laundry inventory system.

आरएफआईडी कपड़े धोने का टैग are designed to survive industrial wash conditions, including washing, drying, ironing, and sterilization. Depending on the use case, they’re built from strong materials like PPS plastic, silicone, or polyester fabric.

These tags are ideal for automating item tracking in hotels, hospitals, laundromats, and linen rental services. Instead of sorting and recording items by hand, you can scan hundreds in seconds—no direct line of sight needed.

It’s like barcodes—but smarter. Barcodes need a direct line of sight. RFID doesn’t. Plus, RFID can scan hundreds of items in seconds.

| विशेषता | Barcode Systems | आरएफआईडी टैग |

| नजर | आवश्यक | Not Needed |

| Scan Speed | 1-2 items/second | 100+ items/second |

| आधार सामग्री भंडारण | सीमित | More Detailed Info |

How They Work

RFID laundry systems have three major components: the tag, the reader, and the backend software.

टैग are small devices embedded in laundry items. These contain a unique identifier and sometimes memory to store basic info like item type or usage count.

पाठकों use radio waves to detect and read tags as they pass through scanning points. These readers are often placed at entry/exit doors, washing machines, or storage shelves.

सॉफ़्टवेयर receives data from the readers and updates the inventory system in real-time. You can view what items were checked in, washed, moved, or delivered—with timestamps.

Here’s what typically happens in a laundry cycle:

टैगिंग: Each item gets a washable RFID tag sewn in or heat-sealed.

Check-in: When items arrive at the laundry, they pass through a reader and get scanned automatically.

Sorting: Software tracks the tagged items and helps staff sort loads more efficiently.

Washing & Drying: Items go through machines as usual. Readers near machines can monitor the progress.

Packing/Delivery: Items are scanned again during packing or dispatch to confirm that everything is accounted for.

Reporting: Managers can access real-time dashboards to track usage, detect missing items, and view performance metrics.

Think of it as GPS, but for laundry. It keeps a digital eye on your textiles from when they enter your facility until they’re returned.

Industrial Laundry RFID Tag's Benefits

Cuts down manual sorting and counting.

Helps prevent lost or misplaced items.

Gives you accurate reports on usage and wear-and-tear.

According to a 2024 report from Grand View Research, RFID use in the laundry sector is projected to grow at over 12% annually. [Source: GVR]

Benefits of RFID Laundry Tags in Laundry Management

Enhanced Tracking

RFID enables real-time tracking. You know exactly where items are in the laundry cycle.

Compare that to manual tracking:

- Manual: Checklists, spreadsheets, room for human error

- RFID: Automated scans, instant updates, 99% accuracy

| Tracking Method | Error Rate |

| Manual | ~10-15% |

| आरएफआईडी | <1% |

Efficiency Improvements

आरएफआईडी कपड़े धोने का टैग automate identification and sorting. When a tagged item moves through a station—sorting, washing, or packing—the RFID reader captures its information instantly. This means items are automatically directed to the next step in the process without human guesswork.

In traditional systems, staff need to inspect and manually sort items visually. With RFID, you eliminate most of that work. This not only speeds up turnaround time but reduces human error and fatigue.

Predicting Linen Lifespan

प्रत्येक Washable RFID tag keeps a digital log of how many times an item has been washed. Once a towel or sheet reaches its limit—say, 200 washes—the system flags it for replacement. This helps you plan for replacements proactively instead of waiting for linens to become unusable.

Some systems alert you when items are close to their end-of-life threshold, giving you time to order new stock and avoid shortages. It’s preventive maintenance—but for fabric.

Optimizing Inventory Management

Because each RFID textile tag has a unique ID, the system always knows how many items you have and where they are. You can scan large batches at once instead of checking things individually. Staff walk by with a handheld reader or pass laundry through a portal, and the system logs the count.

This helps track missing items and reduce over-ordering. If something goes missing, you can trace the last place it was scanned and hold the right people accountable.

Preventing Theft and Reducing Disputes

Large-scale laundry operations—especially those dealing with hotels and hospitals—often face disputes about missing items. Without proper tracking, it’s hard to know if something was lost at the laundry or never returned by the customer.

RFID laundry tags solve this by logging every movement. If an item goes missing, the history can show where it was last scanned. This reduces finger-pointing, builds customer trust, and discourages theft.

Automated Reporting for Smarter Decisions

RFID systems generate detailed reports automatically—no need to dig through files or spreadsheets. You can access usage data, damage rates, loss statistics, and more with just a few clicks.

This gives laundry managers insight into where they’re losing money, which items are used most, and how to adjust inventory and workflows. It’s data-driven management without extra work.

Cost Savings & ROI

You might spend upfront, but the savings are long-term:

- Fewer lost items

- Less labor spent on tracking

- Longer linen lifespan (due to better tracking)

How to Choose the Right RFID Laundry Tag

Choosing the right RFID laundry tag involves several key factors: environment, tag material, size, and frequency range.

Can RFID Tags Be Washed?

Yes, RFID laundry tags are made to handle the full laundry process—washing, drying, and even high-temperature ironing. They’re built from tough materials and designed to last through hundreds of industrial cleaning cycles.

Tag Frequencies: HF vs. UHF

- HF (High Frequency): Often used in small-scale laundry operations: shorter read ranges but better performance near liquids or metals.

- UHF (Ultra High Frequency): Great for large-scale operations like linen rental companies. Longer read ranges and faster scanning of bulk items.

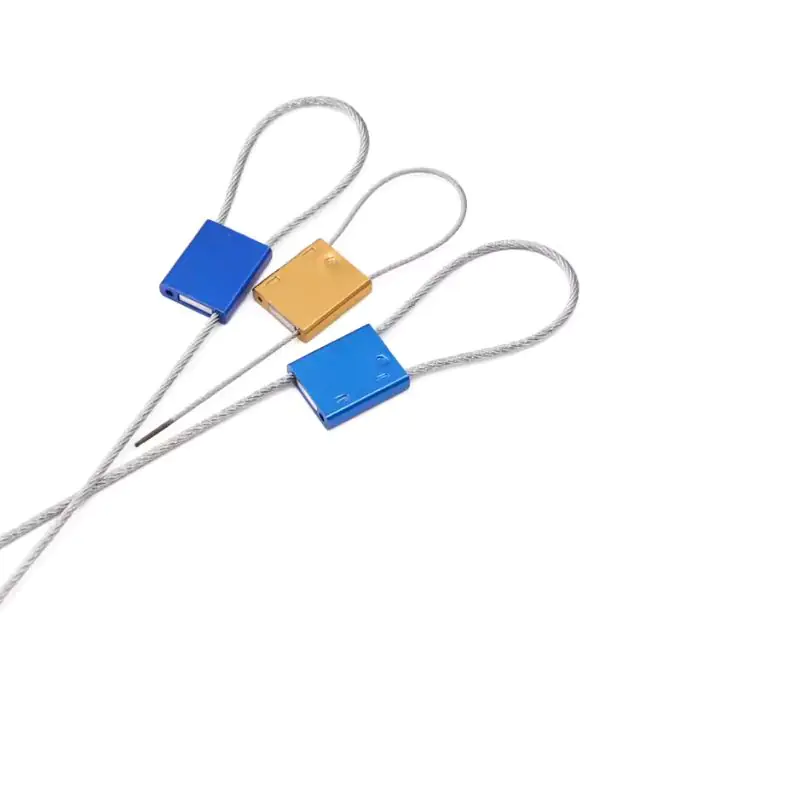

Common Tag Types and Materials

Made from engineering plastic

Resistant to high heat, chemicals, and wear

Available in multiple sizes (φ13mm–φ30mm)

Operates in extreme temperatures up to 200°C

Washable over 200 times

Available in both HF and UHF versions

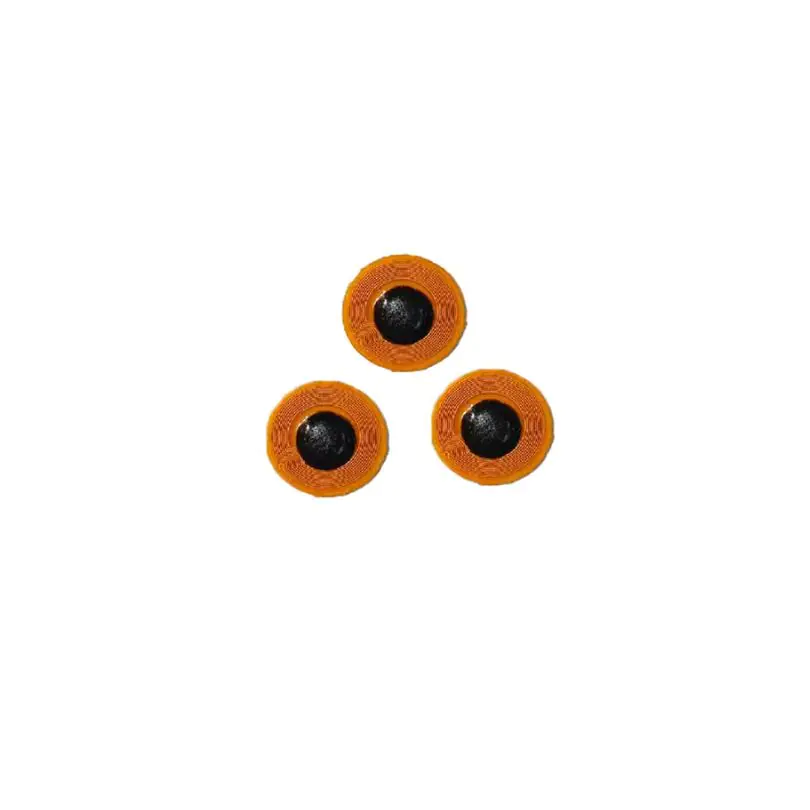

Soft and flexible, easy to sew into garments

Eco-friendly silicone material

Handles high heat (up to 185°F for 60 minutes sterilization)

More than 200 wash cycles

Available in sizes like 55×10mm or 80×24mm

Best for sensitive fabrics or where softness matters

Made with washable cloth

Lightweight, soft, and durable

Withstands 130°C washing and 180°C pre-drying

Good for use in garments where comfort is a concern

Common sizes: 70×15mm, 82×17mm

How to Heat Seal RFID Laundry Tags on Linens and Uniforms

When attaching RFID laundry tags to linens, uniforms, or other washable textiles, heat sealing is fast, durable, and professional, especially when sewing isn’t practical. JIA RFID offers RFID laundry tags with integrated heat-seal adhesive specifically designed for high-temperature environments like industrial laundries, hospitals, and hotels.

What Is Heat Sealing?

Heat sealing involves using a specialized machine, known as a heat sealer, to apply controlled heat and pressure that activates the adhesive layer on the tag. This process melts a thin layer of plastic adhesive, bonding the RFID tag directly to the fabric surface and securing it in place—almost like vacuum sealing it onto the textile.

This ensures the tag remains firmly attached through repeated washes, high-temperature drying, sterilization, and even dry-cleaning cycles.

When to Use Heat Sealing Instead of Sewing

While some RFID laundry tags can be sewn onto garments using a standard needle and thread, heat sealing is ideal when:

- The garment material is too delicate or thick to sew through.

- Speed and consistency are key (e.g., bulk processing).

- You want a cleaner, more discreet tag attachment.

- You don’t want to compromise the tag’s waterproof integrity.

For example, our JIA RFID textile laundry tags have heat-seal adhesive backing that’s activated by heat and pressure, ensuring a secure bond without damaging the fabric.

What You’ll Need

To heat seal RFID laundry tags, you’ll need:

- A heat-sealing machine (flat-head style preferred)

- RFID laundry tags with heat-activated adhesive (like those from JIA RFID)

- Clean, dry textile surface (free of lint or moisture)

Step-by-Step: How to Heat Seal RFID Laundry Tags

- Preheat your heat sealer to the manufacturer’s recommended temperature (typically between 150°C and 200°C / 320°F and 390°F).

- Position the RFID tag on the desired location of the garment or linen, with the adhesive side facing down.

- Apply heat and pressure using the heat sealer, typically 10–15 seconds, depending on machine type and fabric.

- Let it cool naturally for a few seconds. Avoid tugging or folding the fabric immediately after sealing.

- Test for adhesion. The tag should be flat, smooth, and firmly attached with no corners peeling up.

Watch Our Video about Heat Seal Process

Can I Still Sew the Tags?

Yes! Our RFID laundry tags are dual-purpose, meaning you can sew or heat-seal them, depending on your needs and workflow. This flexibility makes them ideal for all garments, from light medical linens to heavy-duty industrial uniforms.

How to Decide?

- Use PPS tags for heavy-duty environments and the longest durability.

- Go with silicone tags if you need flexibility and soft embedding in clothes.

- Choose polyester tags when you want a lower-cost, cloth-like option.

Tips Before You Buy:

- Request tag samples for testing in your machines.

- Confirm tag compatibility with your RFID readers.

- Make sure the size and material won’t interfere with user comfort or cleaning.

Frequently Asked Questions About RFID Laundry Tags

How do RFID tags work in a laundry system?

Scanners read tags at key points in the workflow—like wash stations or delivery zones—and instantly update your inventory system.

Can RFID tags really survive 200 washes?

Yes. Industrial-grade RFID tags like PPS and silicone models are tested for high-temperature and high-pressure cycles.

Do RFID laundry tags affect the comfort of garments?

Not really. Most RFID tags, especially polyester and silicone types, are soft, lightweight, and sewn into seams where they don’t interfere with comfort.

What happens if a tag is damaged or stops working?

The software will flag the item as unreadable. You can replace the tag and reassign it to the item in your system. Regular inspections help catch this early.

Are RFID laundry tags safe in hospital or medical environments?

Yes. Many RFID tags are sterilization-ready and built to withstand the high temperatures and chemicals used in medical laundry processes.

Can RFID tags be reused if linens are replaced?

In most cases, no. The tags are sewn or sealed into the fabric and are meant to stay with the item for its lifespan. Depending on the application, some tags may be recoverable.

Final Thoughts on RFID Laundry Tags

RFID tags aren’t just a tech upgrade—they’re a shift in how you manage laundry. With better tracking, faster inventory handling, and data to back decisions, you’re not just saving time—you’re improving service quality.

Whether you run a small laundry shop or manage textiles in a hospital, RFID gives you more control, more insights, and less hassle.

Start with a few tags, test them in your current setup, and grow from there. The technology’s here, ready to help you work smarter.

Request a Quote or Free Sample

If you’re ready to take control of your laundry operations, now’s the time.

📩 Contact us for a free sample or quote

📱 Or WhatsApp us: +86 138 2318 6864

टिप्पणियाँ

गर्म उत्पाद

RFID Laundry Tag Guide 2025: Smarter Tracking, Less Waste, and Real Results

Did you know that smart RFID systems can reduce laundry losses by up to 95%? That’s a game-changer for laundry businesses that lose time and money tracking items manually.

How RFID Tags for Pallet Streamline Tracking in Warehouses

Pallet-level tracking is critical for inventory accuracy, operational efficiency, and real-time visibility in today’s fast-paced logistics and supply chain environments.

Top 5 Types RFID Tag for Warehouse Automation

Warehouse operations are becoming more complex, and manual tracking methods can’t keep up. RFID tags for warehouse automation enable real-time data capture, faster inventory processing, and better traceability.

RFID Smart License Plates Help Hengshui to Track The E-Bikes

As urbanization accelerates and the green travel movement gains momentum, electric bicycles have become vital to daily commuting in Hengshui, Henan Province.

पीसीबी टैग क्या है?

जानें कि कैसे नवीन टैग और आरएफआईडी समाधान खुदरा और रसद से लेकर स्वास्थ्य सेवा और शिक्षा तक के उद्योगों को बदल देते हैं।

आरएफआईडी बनाम एनएफसी: आरएफआईडी और एनएफसी के बीच मुख्य अंतर

यह लेख RFID और NFC के बीच अंतरों का पता लगाता है, जो व्यावसायिक परिचालन में क्रांति लाने वाली दो प्रौद्योगिकियां हैं।

टैग

संबंधित ब्लॉग

RFID Laundry Tag Guide 2025: Smarter Tracking, Less Waste, and Real Results

Did you know that smart RFID systems can reduce laundry losses by up to 95%? That’s a game-changer for laundry businesses that lose time and money tracking items manually.

How RFID Tags for Pallet Streamline Tracking in Warehouses

Pallet-level tracking is critical for inventory accuracy, operational efficiency, and real-time visibility in today’s fast-paced logistics and supply chain environments.

Top 5 Types RFID Tag for Warehouse Automation

Warehouse operations are becoming more complex, and manual tracking methods can’t keep up. RFID tags for warehouse automation enable real-time data capture, faster inventory processing, and better traceability.