Come funzionano i tag RFID su superfici metalliche?

Sommario

Tag RFID su metallo: Come funzionano e perché gli acquirenti industriali ne hanno bisogno

Perché i tag RFID standard faticano sulle superfici metalliche

I tag RFID standard, pur essendo convenienti e ampiamente utilizzati, non sono progettati per funzionare in modo affidabile sulle superfici metalliche. Non siete i soli se state cercando di etichettare apparecchiature, strumenti o contenitori metallici con i normali tag RFID e riscontrate errori di lettura o prestazioni irregolari. Ecco perché succede:

1. Riflessione e interferenza del segnale

Le onde radio emesse da un lettore RFID rimbalzano sulle superfici metalliche, generando un'interferenza multi-path. Ciò significa che il segnale si disperde in modo imprevedibile, confondendo il lettore RFID e provocando:

- Letture mancate

- Lettura di tag duplicati

- Accuratezza di lettura ridotta

Esempio: In un magazzino, la scansione di uno scaffale metallico di prodotti può dare luogo a letture incoerenti a causa delle riflessioni del segnale.

2. Detuning dell'antenna

I tag RFID contengono antenne progettate per risuonare a frequenze specifiche (come UHF o HF). Quando un tag viene posizionato su un metallo, la superficie conduttiva altera il campo elettromagnetico, disallineando l'antenna e rendendo il tag inefficace.

Questo porta a:

- Perdita completa del segnale

- Scarsa comunicazione tra tag e lettore

- Campo di lettura gravemente ridotto

Analogia: È come usare una radio sintonizzata sulla frequenza sbagliata: la connessione non funziona.

3. Scarico di potenza nei tag passivi

Le etichette RFID passive si affidano all'energia del segnale del lettore RFID per alimentare il chip e inviare i dati. Ma le superfici metalliche assorbono o deviano questa energia, lasciando al tag una potenza insufficiente per funzionare.

Ne consegue che:

- Tag non attivati

- Trasferimento parziale dei dati

- Riduzione della durata di vita dei tag nelle applicazioni mission-critical

Impatto: In ambienti industriali con macchinari metallici di grandi dimensioni o imballaggi metallici, i tag passivi spesso non funzionano se non sono adeguatamente schermati.

4. Zone di lettura non coerenti

Quando si utilizzano tag RFID standard in prossimità o su metallo:

- La zona di lettura diventa imprevedibile

- I tag funzionano in alcune posizioni ma non in altre

- L'affidabilità del sistema diminuisce, frustrando gli operatori e ritardando i flussi di lavoro

In sintesi: Le etichette metalliche standard compromettono l'accuratezza operativa e il ROI se ci si affida all'RFID per la tracciabilità in tempo reale e la visibilità dell'inventario.

Cosa sono i tag RFID su metallo?

I tag RFID on-metal (chiamati anche tag RFID anti-metal o tag RFID metal-mount) sono transponder RFID appositamente progettati per funzionare efficacemente su o vicino a superfici metalliche, cosa che i tag RFID tradizionali non possono fare in modo affidabile.

Queste etichette non sono solo versioni leggermente modificate delle normali etichette RFID, ma sono costruite appositamente utilizzando materiali avanzati e strategie di progettazione per superare le interferenze indotte dal metallo.

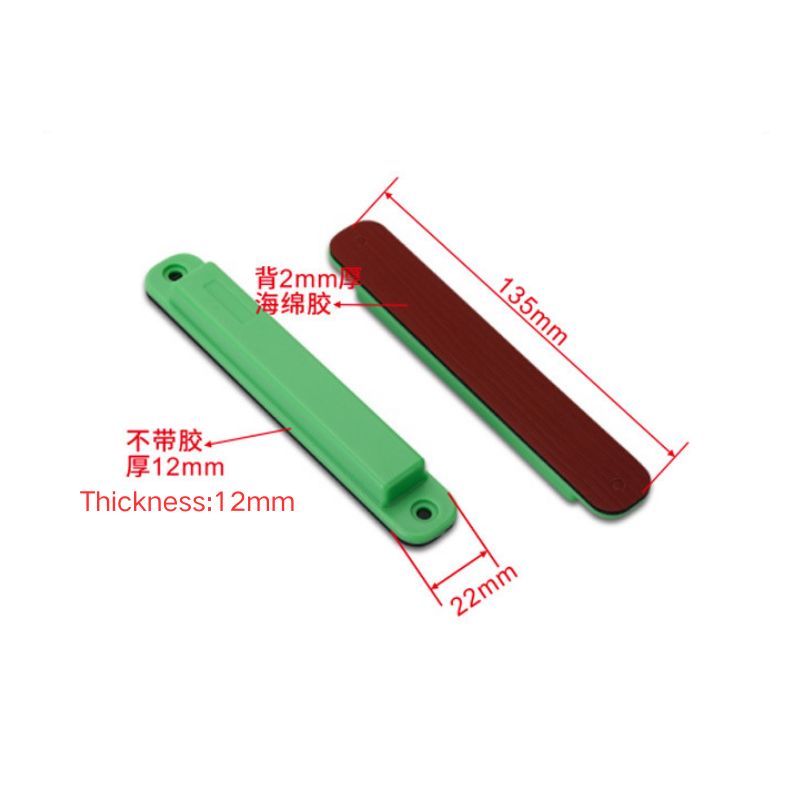

Come sono costruiti

Per funzionare sul metallo, queste etichette includono:

Strati isolanti: Separare l'antenna e il chip RFID dalla superficie metallica per evitare il distacco.

Supporto in ferrite: Uno strato magnetico che reindirizza i campi elettromagnetici, consentendo una trasmissione pulita del segnale.

Antenne ottimizzate: Progettate esplicitamente per ambienti a campo vicino con superfici conduttive.

Alloggiamenti resistenti: Materiali come l'ABS, l'epossidico o gli involucri metallici proteggono il tag dagli abusi industriali, come vibrazioni, polvere, olio o umidità.

Questi componenti lavorano insieme per garantire che il tag trasmetta i dati in modo affidabile anche quando viene montato direttamente su strumenti metallici, macchinari, veicoli o container.

Varianti di design

I tag RFID su metallo sono disponibili in varie forme e dimensioni per soddisfare le vostre esigenze operative, tra cui:

- Cartellini piatti per il montaggio su scaffali o contenitori metallici.

- Targhette curve o flessibili per tubi e apparecchiature cilindriche.

- Targhette per monete robuste da inserire in strumenti o beni metallici.

- Etichette con spaziatura in schiuma per applicazioni economiche e monouso.

Visualizza l'elenco completo Linea di prodotti di tag RFID su metallo

Come funzionano i tag RFID su metallo: Ingegneria che supera le interferenze

La tecnologia RFID si basa su una comunicazione fluida tra un lettore e un tag tramite onde a radiofrequenza. Tuttavia, questa comunicazione viene interrotta dall'introduzione di metalli nell'ambiente, a meno che il tag non sia specificamente progettato per funzionare in tali condizioni.

È proprio per questo che le etichette RFID su metallo sono costruite.

La sfida centrale: Il metallo disturba i campi elettromagnetici

Nei sistemi RFID standard, l'antenna all'interno del tag risuona a una frequenza specifica (in genere UHF o HF). Quando viene posizionato su un metallo:

- La frequenza di risonanza dell'antenna cambia (detuning)

- Il segnale radio è assorbito o riflesso in modo imprevedibile

- La comunicazione tra il lettore e il tag diventa instabile o si interrompe completamente.

Le etichette RFID on-metal utilizzano un design a più livelli per superare queste sfide.

Punti di forza per i tag RFID standard e i tag RFID su metallo

| Caratteristica | Tag RFID standard | Tag RFID su metallo |

| Funziona su superfici metalliche | ❌ Segnale debole o non funzionante | ✅ Progettato per il metallo |

| Campo di lettura vicino al metallo | ⛔ Gravemente ridotto | Fino a 10 metri (UHF) |

| Resistenza alle interferenze | ❌ Inaffidabile | ✅ Schermatura a base di ferrite |

| Durata in ambienti difficili | ⚠️ Limited | Materiali certificati IP67+ |

Avete bisogno di aiuto per scegliere l'etichetta giusta?

Il team di ingegneri di JIA RFID offre consulenze gratuite e soluzioni personalizzate per i clienti industriali. Siamo in grado di consigliare il prodotto perfetto per il monitoraggio di macchinari pesanti, container o attrezzature in ambienti difficili.

Parlate con uno specialista RFID →

Esplora i lettori RFID portatili →

Applicazioni industriali delle etichette RFID su metallo

I tag RFID su metallo rappresentano una svolta per i settori che si basano su strumenti, parti, strutture e apparecchiature metalliche. A differenza dei tag tradizionali, questi sono costruiti per ambienti robusti e pesanti come il metallo, dove precisione, durata e dati in tempo reale sono essenziali.

Di seguito sono riportati i settori chiave e le applicazioni reali in cui i tag on-metal diretti in fabbrica di JIA RFID migliorano le operazioni, riducono i costi e migliorano la tracciabilità.

1. Apparecchiature industriali e di produzione

Casi d'uso:

- Tracciamento di utensili, stampi e attrezzature in produzione

- Monitoraggio degli articoli in corso di lavorazione (WIP) che si spostano tra le stazioni

- Identificazione delle macchine metalliche per la programmazione della manutenzione

Benefici:

Assicura la responsabilità degli utensili, riduce i ritardi di produzione e supporta la manutenzione preventiva grazie alla visibilità in tempo reale.

Prodotto correlato: Tag RFID per dischi e monete →

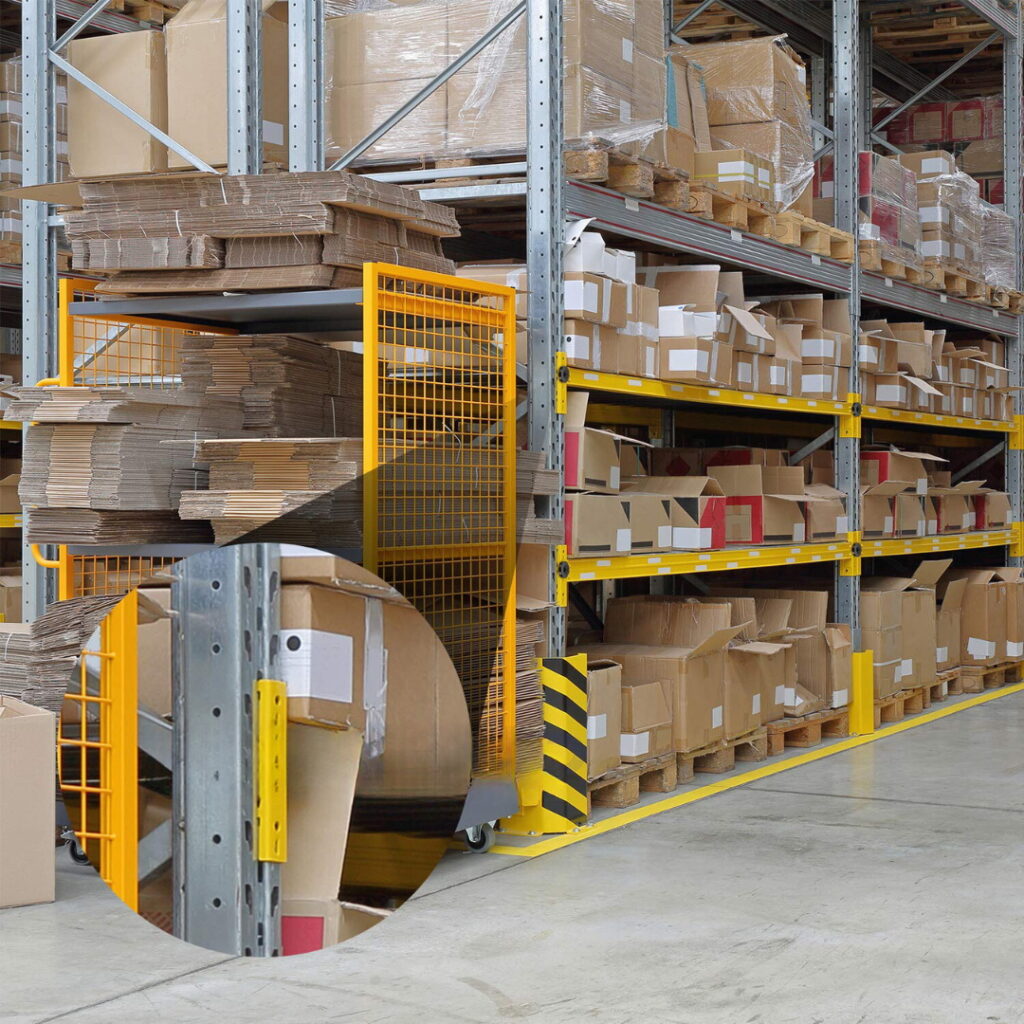

2. Logistica e magazzino

Casi d'uso:

- Gestione di contenitori metallici per spedizioni, pallet e casse.

- Tracciamento degli articoli di trasporto restituibili (RTI).

- Automatizzazione della scansione di ingresso/uscita con lettori portatili.

Benefici:

Elimina la scansione manuale, riduce la perdita di beni e accelera le verifiche dell'inventario grazie alla capacità di lettura in blocco.

Prodotto correlato: Lettori RFID portatili →

3. Petrolio e gas

Casi d'uso:

- Identificazione e tracciabilità di tubi, valvole e flange in metallo.

- Monitoraggio delle attrezzature di perforazione sulle piattaforme offshore

- Mantenimento dei registri di ispezione e certificazione

Benefici:

Migliora la conformità alla sicurezza e la tracciabilità degli asset in ambienti corrosivi e ad alta temperatura, dove le etichette con codice a barre falliscono.

Perché la RFID vince: Le etichette su metallo resistono all'acqua, alla pressione e alle sostanze chimiche che comunemente degradano le etichette di tracciamento standard.

4. Aerospaziale e aviazione

Casi d'uso:

- Tracciamento di parti di aeromobili e componenti strutturali

- Gestione degli strumenti e delle apparecchiature di calibrazione negli hangar

- Automatizzazione della documentazione MRO (Maintenance, Repair, Overhaul)

Benefici:

Migliora la tracciabilità dei componenti mission-critical, riducendo al contempo la documentazione cartacea e gli errori umani negli ambienti sensibili alla sicurezza.

Bonus: I tag RFID metal-safe soddisfano i requisiti dell'aviazione e resistono alle vibrazioni e alle fluttuazioni di pressione.

5. Costruzioni e infrastrutture

Casi d'uso:

Taglio di travi in acciaio, impalcature e attrezzature metalliche.

Tracciamento di strumenti e attrezzature mobili di alto valore

Registrazione delle ispezioni sui componenti dell'edificio

Benefici:

Riduce la perdita di attrezzature, previene l'accumulo di utensili e garantisce la conformità agli standard di sicurezza del sito.

6. Gestione delle risorse IT e centri dati

Casi d'uso:

Etichettatura e inventario dei server metallici e dei dispositivi di rete

Protezione di unità di backup, rack e carrelli mobili

Supporto agli audit con la scansione RFID portatile

Benefici:

Accelera i rapporti di conformità, riduce al minimo gli errori manuali e supporta la tracciabilità degli asset nelle sale server ad alta densità.

Migliorare con: Lettori RFID per centri dati →

Siete pronti a etichettare i beni metallici in scala?

JIA RFID offre prezzi all'ingrosso, kit di campioni e soluzioni personalizzate per adattarsi alle vostre applicazioni, indipendentemente dalle condizioni difficili.

Perché acquistare da JIA RFID?

In qualità di produttore diretto, JIA RFID offre:

- Supporto alla progettazione personalizzata per superfici metalliche uniche

- Prezzi all'ingrosso competitivi con tempi di consegna rapidi

- Spedizione globale per clienti B2B

- Ingegneria interna per ambienti specializzati

Esplora altri tipi di tag RFID:

🔹 Tag RFID per dischi e monete

🔹 Lettori RFID portatili

Prodotto in evidenza: Caratteristiche dell'etichetta RFID su metallo

- Frequenza: Opzioni UHF (860-960 MHz) o HF

- Portata di lettura: Fino a 10 metri (UHF)

- Grado di protezione IP: IP67+ per ambienti industriali

- Opzioni di montaggio: Adesivo, vite, rivetto

Domande frequenti

Le etichette RFID funzionano davvero sul metallo?

Sì. I tag RFID su metallo sono progettati per gestire le interferenze metalliche e sono quindi ideali per l'etichettatura di strumenti, macchinari e attrezzature metalliche.

Quanto costano le etichette RFID su metallo?

I prezzi variano a seconda del tipo e del volume. Per le versioni passive, i prezzi per le grandi quantità partono da $0,50 per etichetta. Richiedete preventivi personalizzati per il vostro settore.

I vostri tag RFID sono impermeabili e resistenti al calore?

Sì, molti dei nostri tag RFID su metallo soddisfano gli standard IP67+ e sono progettati per essere utilizzati in ambienti industriali difficili.

Posso provarli prima di acquistarli?

Assolutamente sì. Offriamo campioni gratuiti per progetti qualificati. Contattateci per un supporto alla valutazione.

Commenti

Prodotti caldi

RFID nella logistica: come eliminare gli errori di instradamento RFID e i malfunzionamenti delle etichette RFID

L'RFID nella logistica è molto più di un semplice strumento per velocizzare i processi. È diventato un elemento fondamentale nel funzionamento delle moderne catene di approvvigionamento.

Che cos'è la gestione dei rifiuti RFID

Immaginate una città in cui ogni bidone della spazzatura parla, non letteralmente, ma attraverso un minuscolo chip che comunica al sistema quando è pieno, quando viene svuotato e dove viene portato. Questo è ciò che fa oggi la gestione dei rifiuti RFID.

Cosa sono le guarnizioni per bulloni e le loro applicazioni? | Guida completa

Nel commercio globale e nella logistica, i sigilli a bullone svolgono un ruolo cruciale nel garantire la sicurezza e la conformità del carico. Questi piccoli ma potenti dispositivi sono progettati per bloccare container, rimorchi e porte di carico con un meccanismo antimanomissione.

Che cos'è un RFID Card Protector? Vantaggi, casi d'uso e guida all'acquisto

La tecnologia RFID (Radio Frequency Identification) è ovunque: nelle carte di credito, nei badge, nei pass di transito, nelle chiavi delle camere d'albergo e altro ancora. Offre velocità e comodità, ma apre anche la porta a un nuovo tipo di furto digitale chiamato "skimming". È qui che entra in gioco una protezione per carte RFID.

Braccialetti RFID per eventi: Guida all'acquisto di prodotti sfusi per gli organizzatori

I braccialetti RFID per eventi stanno diventando la soluzione ideale per gli organizzatori che hanno bisogno di ingressi più rapidi, prevenzione delle frodi e pagamenti senza contanti a concerti, festival e impianti sportivi. A differenza dei biglietti cartacei o dei codici QR, questi braccialetti intelligenti utilizzano chip incorporati per semplificare l'accesso, proteggere le transazioni e migliorare l'esperienza degli ospiti.

Come l'etichetta RFID sul parabrezza migliora il controllo degli accessi dei veicoli e i sistemi di pedaggio

Nel mondo frenetico di oggi, l'identificazione dei veicoli deve essere rapida, sicura e senza contatto. Un'etichetta RFID sul parabrezza offre proprio questo: un modo affidabile per gestire i pedaggi, i parcheggi e gli accessi senza fermare i veicoli.

Etichette

BLOG CORRELATI

RFID nella logistica: come eliminare gli errori di instradamento RFID e i malfunzionamenti delle etichette RFID

L'RFID nella logistica è molto più di un semplice strumento per velocizzare i processi. È diventato un elemento fondamentale nel funzionamento delle moderne catene di approvvigionamento.

Che cos'è la gestione dei rifiuti RFID

Immaginate una città in cui ogni bidone della spazzatura parla, non letteralmente, ma attraverso un minuscolo chip che comunica al sistema quando è pieno, quando viene svuotato e dove viene portato. Questo è ciò che fa oggi la gestione dei rifiuti RFID.

Cosa sono le guarnizioni per bulloni e le loro applicazioni? | Guida completa

Nel commercio globale e nella logistica, i sigilli a bullone svolgono un ruolo cruciale nel garantire la sicurezza e la conformità del carico. Questi piccoli ma potenti dispositivi sono progettati per bloccare container, rimorchi e porte di carico con un meccanismo antimanomissione.