Application

RFID uses electromagnetic fields to automatically identify and track tags on objects. An RFID system includes a tag (radio transponder), a receiver, and a transmitter. Widely applied ub various industries.

Industry & Logistics

RFID is an incredibly versatile technology with applications across various business sectors, from controlling manufacturing processes and maintaining equipment to managing assets and tracking goods through distribution. RFID systems benefit businesses of all sizes by enhancing efficiency and reducing costs through process automation and improved asset utilization. It serves as the foundation for effective asset management systems and plays a crucial role in the Internet of Things (IoT).

Access & Security

RFID tags have been utilized in access control and security systems for several years. Today, automatic identification systems are essential for addressing security threats. An RFID-based access system permits only authorized individuals to enter or exit specific checkpoints. These individuals receive unique tags that grant them access to designated areas.

Livestock Management

In livestock management, RFID is used to identify and track animals such as cows, pigs, and goats. Beyond identification, RFID tags and software store an animal’s complete history, including weight, age, sex, birthing details, offspring, and medical records. Veterinarians can scan a tag to access detailed health information. This is part of the “smart farming” trend, which leverages IoT technologies for comprehensive livestock management.

Laundry Management

The laundry management system uses RFID technology to track laundry in and out of a facility, helping monitor fabric lifespan and maintain optimal stock levels. We enable companies to automatically track linens, clothing, and other assets for accurate inventory management. RFID tags are designed to withstand pressure, heat, and chemicals, making them ideal for textile rental and dry cleaning. Each laundry transponder has a unique ID, allowing easy garment identification, minimizing shortages, and saving handling time throughout the laundering process.

Waste Management

Radio Frequency Identification (RFID) is a valuable tool for waste collection, disposal, and management, offering significant benefits to city governments and waste removal contractors. The technology improves waste management efficiency by enabling traceability and real-time visibility in operations.

Our factory provides a wide range of LF and UHF passive contactless transponders designed to withstand water, shock, and temperature variations, making them ideal for harsh outdoor environments. Disposal trucks equipped with RFID tags scan waste bins with RFID readers, recording the time and location at which each bin is emptied. This automated data collection ensures faster, cheaper, and more accurate reporting.

Inventory Management

Managing inventory has become increasingly challenging due to the growing complexities in the work process. An inventory management system provides clear insights into stock levels, preventing surpluses and shortages and ensuring stock security and quality control. Inventory visibility and control are critical for maximizing throughput and boosting productivity. RFID technology enhances this by creating real-time visibility and control in warehouse operations.

RFID enables the identification and tracking of individual products and components throughout the supply chain, from production to point-of-sale, without requiring direct line-of-sight. It ensures complete visibility of stock on hand, allowing for better utilization. Every inventory movement is automatically recorded in the system, streamlining inventory management.

Electronic Toll Collection

Toll collection involves gathering taxes from road users, but manual tolling often leads to long lines, road congestion, and increased vehicle pollution.

An Electronic Toll Collection (ETC) system automates this process by charging tolls directly to a customer’s account without requiring the vehicle to stop. An RFID tag attached to the vehicle’s windshield communicates with the toll reader, allowing automatic deductions from the linked account as the vehicle passes.

In summary, ETC is an RFID-based system that assigns a unique ID to each vehicle. When the vehicle approaches the toll, the system automatically deducts the toll and opens the gate. This method reduces manual labor, delays, and road pollution while cutting management costs.

Warehousing & Distribution

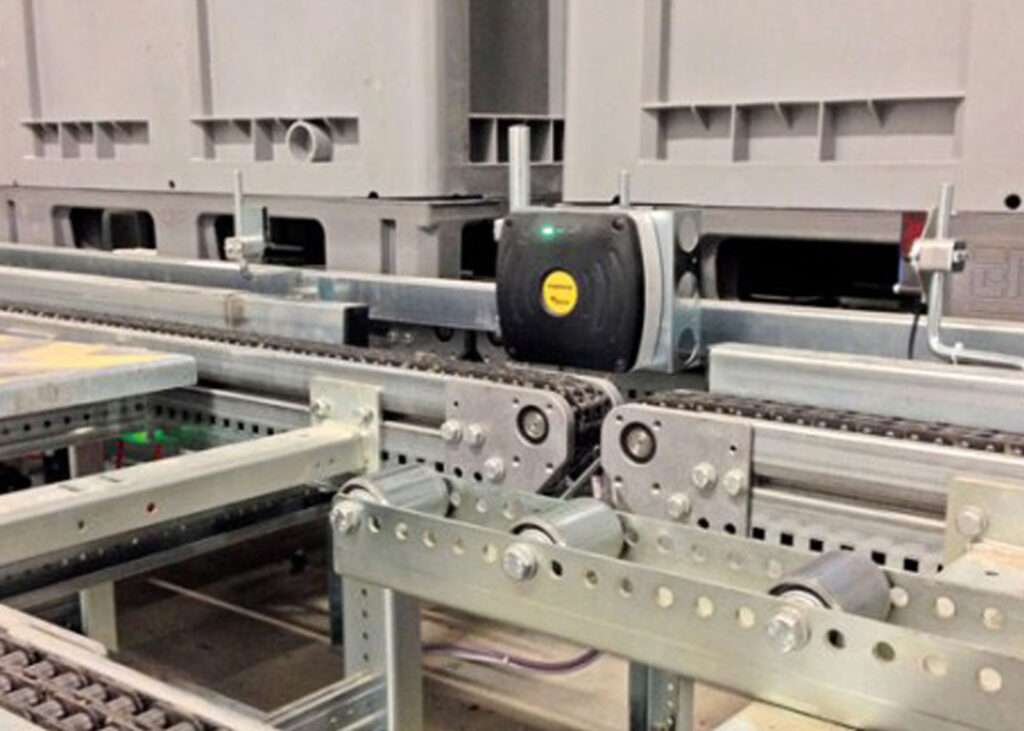

Warehouse management is vital across all industries, and RFID technology plays a key role in enhancing efficiency. It tracks, secures, and manages items from their entry into the warehouse through transit, providing real-time asset traceability and improving responsiveness.

RFID enables automatic identification, maintaining accurate records of location and movement. Tags are attached to materials, while readers and antennas at entry and exit points capture asset movements. Handheld RFID devices facilitate regular inventory updates, allowing simultaneous data updates for multiple items. With the capacity to read over 100 tags at once, increased readers and antennas ensure continuous material monitoring.

Jewelry Management

Inventory management in the jewelry industry is vital but time-consuming, requiring regular checks across manufacturing, wholesale, and retail. Even minor losses can be costly.

RFID tagging streamlines this process by enabling bulk reading of jewelry items, which speeds up stock-taking and reduces manual errors. Omnia’s RFID + EAS tags combine inventory management with theft prevention, providing an innovative solution to address multiple challenges faced by jewelers.

Tire Tracking

Radio Frequency Identification (RFID) is experiencing rapid adoption within the tire industry, driven by the need for more efficient tracking, inventory management, and product lifecycle monitoring. As tires play a critical role in various industries, including automotive, aviation, and logistics, accurate tracking of each tire’s production, distribution, and usage history has become essential. RFID technology enables manufacturers, distributors, and end-users to gain real-time visibility into tire data, offering several key advantages over traditional barcodes and manual tracking methods.