Can RFID On Metal Tags Be Used on Metallic Objects?

- Zhou, Ray

- 03/09/2024

Table of Contents

Introduction to RFID On Metal Tags

In this article, we’ll explain how On Metal RFID Tags work, why they’re effective, and how you can implement them in your operation. You’ll also discover real-world use cases, best practices, product recommendations, and expert-backed answers to the most common questions.

Why Is Using RFID Tags on Metal Surfaces Challenging?

Metal surfaces pose a unique challenge for standard RFID tags. The conductive properties of the metal can interfere with the tag’s performance in several ways:

- Signal absorption: Metal tends to absorb radio waves, reducing the tag’s read range.

- Detuning: The proximity to metal can alter the tag’s antenna frequency, affecting its ability to communicate with readers.

- Reflection: Metal surfaces can reflect radio waves, creating interference and reducing read accuracy.

These factors can significantly impact the performance of regular RFID tags when applied to metallic objects, leading to reduced read ranges, inconsistent readings, or complete failure to detect the tag.

How RFID On Metal Tags Work

Traditional RFID tags fail or perform poorly when placed directly on metal. This is because metal reflects and absorbs radio frequency (RF) signals, disrupting communication between the tag and reader. However, RFID On Metal Tags are specifically engineered to overcome this.

Key Design Features:

| Feature | Description |

|---|---|

| Dielectric Spacer Layer | Separates the tag antenna from the metal surface to reduce interference |

| Specialized Antenna Design | Tuned to operate efficiently in proximity to metallic surfaces |

| Encapsulation | Tags are often ruggedized for harsh industrial environments (outdoor, high-temperature, chemical exposure) |

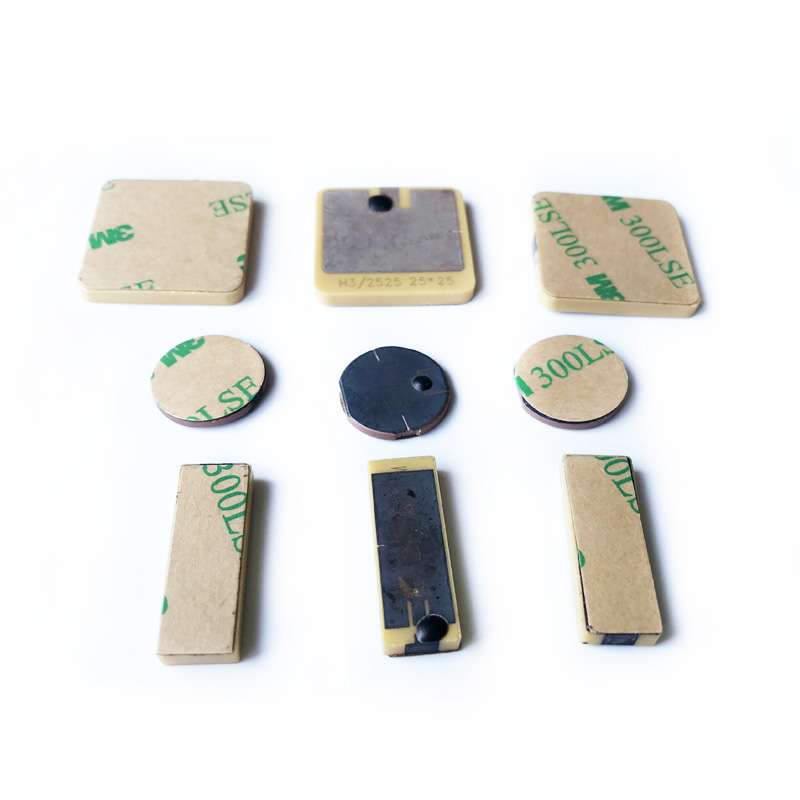

| Mounting Flexibility | Adhesive, screw, magnetic, or welded mounting options available |

These features allow Metal Mount RFID Tags to perform reliably even when affixed directly to steel, aluminum, copper, or other metal surfaces.

Standard RFID Tags vs RFID On Metal Tags

| Feature | Standard RFID Tags | RFID On Metal Tags |

|---|---|---|

| Performance on Metal | Poor | Excellent |

| Read Range on Metal | Severely limited | Optimized (up to 6–10 meters) |

| Durability | Limited | Rugged, industrial-grade |

| Mounting Options | Flat surfaces only | Screws, magnets, adhesives, welding |

| Cost | Lower | Higher (but long-term ROI) |

What Are the Benefits of Using On-Metal RFID Tags?

Implementing RFID on metal tags in your asset tracking or inventory management system can offer numerous advantages:

- Improved accuracy: On-metal tags provide consistent and reliable readings on metallic surfaces.

- Extended read ranges: Specially designed antennas allow for better performance, even in challenging environments.

- Versatility: These tags can be used on both metal and non-metal surfaces, simplifying inventory processes.

- Durability: Many on-metal tags are built to withstand harsh industrial environments.

- Cost-effective tracking: Despite higher initial costs, on-metal tags can reduce expenses associated with lost or mismanaged assets.

By leveraging on-metal RFID technology, businesses can enhance their operational efficiency and gain better visibility into their metal-based assets.

Real-World Use Cases for RFID On Metal Tags

1. Industrial Asset Tracking

Factories use On Metal RFID Tags to track heavy machinery, manufacturing tools, and spare parts throughout production floors.

2. IT Asset Management

Data centers mount Metal Mount RFID Tags to servers, racks, and network devices to monitor hardware movement and reduce inventory loss.

3. Oil & Gas Equipment Monitoring

Pipelines, valves, and high-pressure containers use RFID On Metal Tags for maintenance scheduling, inspections, and compliance logging.

4. Aerospace & Defense Logistics

Aircraft components and weapons storage often require On Metal RFID Tags for chain-of-custody tracking and lifecycle management.

5. Tool Management Systems

Mining, construction, and aviation industries attach Metal Mount RFID Tags to high-value tools to prevent loss and misuse.

How Do You Choose the Right On-Metal RFID Tag for Your Application?

Selecting the appropriate on-metal RFID tag requires careful consideration of several factors:

- Environment: Consider temperature, humidity, and exposure to chemicals or physical stress.

- Read range requirements: Determine the distance at which tags need to be readable.

- Size constraints: Ensure the tag dimensions are suitable for your application.

- Frequency: Choose between UHF (Ultra High Frequency) and HF (High Frequency) based on your needs.

- Attachment method: Decide between adhesive backing, screws, or welding for secure attachment.

- Compliance: Verify that the tag meets relevant industry standards and regulations.

By evaluating these factors, you can select an on-metal RFID tag that best suits your specific application and environment.

What Are Some Best Practices for Implementing On-Metal RFID Tags?

To maximize the effectiveness of your on-metal RFID system, consider the following best practices:

- Conduct a site survey to identify potential sources of interference.

- Test different tag placements to optimize read performance.

- Use high-quality readers and antennas designed for metal-rich environments.

- Implement proper tag management software to organize and analyze data.

- Train staff on proper tag application and handling techniques.

- Regularly maintain and calibrate your RFID equipment.

- Consider a pilot program before full-scale implementation to identify and address any issues.

By following these guidelines, you can ensure a smooth and successful deployment of on-metal RFID technology in your organization.

What Are the Latest Innovations in On-Metal RFID Technology?

The field of on-metal RFID technology is constantly evolving, with new innovations emerging to address specific challenges and expand capabilities:

- High-temperature resistant tags: Designed for use in extreme environments, such as automotive paint shops or industrial ovens.

- Printable on-metal tags: Allowing for customization and integration with existing labeling systems.

- Ultra-thin profiles: New materials and designs enable slimmer on-metal tags for space-constrained applications.

- Enhanced read ranges: Advancements in antenna design push the boundaries of on-metal tag performance.

- Multi-surface tags: Hybrid designs that perform well on both metal and non-metal surfaces.

These innovations continue to expand the possibilities for RFID technology in metal-rich environments, opening up new applications and improving existing systems.

What Does the Future Hold for On-Metal RFID Technology?

As technology continues to advance, the future of on-metal RFID looks promising:

- Integration with IoT: On-metal RFID tags may become key components in the Internet of Things ecosystem, providing real-time data on metal assets.

- Enhanced sensor capabilities: Future tags might incorporate additional sensors for temperature, humidity, or shock detection.

- Improved energy harvesting: Advancements may lead to more efficient power management, extending tag life and capabilities.

- Miniaturization: Ongoing research aims to create even smaller on-metal tags without sacrificing performance.

- Artificial Intelligence integration: AI algorithms may enhance data analysis and predictive maintenance capabilities.

These developments suggest that on-metal RFID technology will play an increasingly important role in asset management and tracking across various industries. In conclusion, RFID tags can indeed be used effectively on metallic objects, thanks to specialized on-metal tag designs. These innovative solutions overcome the challenges posed by metal surfaces, offering reliable performance and opening up new possibilities for asset tracking and inventory management. As technology continues to evolve, on-metal RFID tags will likely become even more versatile and integral to modern business operations.

FAQs About RFID On Metal Tags

Do RFID tags work on metal?

Standard RFID tags do not work well on metal due to RF interference. However, RFID On Metal Tags are specially designed to function accurately on metallic surfaces, using shielding and antenna tuning technologies.

What industries use On Metal RFID Tags the most?

Manufacturing, oil & gas, aerospace, data centers, logistics, and construction industries frequently use Metal Mount RFID Tags for high-value or heavy-duty asset tracking.

What’s the typical read range of an On Metal RFID Tag?

It depends on the tag design and reader setup. Most high-performance On Metal RFID Tags offer 1 to 10 meters of read range on metal.

Are On Metal RFID Tags reusable?

Yes. Most industrial-grade tags are highly durable and can be reused for years, even in outdoor or hazardous conditions.

Can On Metal RFID Tags be mounted with magnets?

Yes. Many Metal Mount RFID Tags support magnetic mounting, which is ideal for temporary or mobile tracking applications.

Ray Zhou

This article was written by Ray Zhou, an RFID technology expert with more than 10 years of industry experience.

Comments

Hot Products

RFID in Logistics: How to Eliminate RFID Misrouting and RFID Label Failures

RFID in logistics is more than just a tool to speed up processes. It has become a key part of how modern supply chains operate.

What Is RFID Waste Management

Imagine a city where every trash bin speaks — not literally — but through a tiny chip that tells the system when it’s full, when it’s emptied, and where it went. That’s what RFID waste management is doing today.

What are Bolt Seals and their Applications? | Complete Guide

In global trade and logistics, bolt seals play a crucial role in ensuring cargo security and compliance. These small but powerful devices are designed to lock shipping containers, trailers, and cargo doors with a tamper-evident mechanism.

What is an RFID Card Protector? Benefits, Use Cases, and Buying Guide

RFID technology (Radio Frequency Identification) is everywhere: in your credit cards, ID badges, transit passes, hotel room keys, and more. It offers speed and convenience, but it also opens the door to a new kind of digital theft called “skimming.” That’s where an RFID card protector comes in.

RFID Wristbands for Events: Bulk Buying Guide for Organizers

RFID wristbands for events are becoming the go-to solution for organizers who need faster entry, fraud prevention, and cashless payments at concerts, festivals, and sports venues. Unlike paper tickets or QR codes, these smart wristbands use embedded chips to streamline access, secure transactions, and improve the guest experience.

How RFID Tag on Windscreen Improves Vehicle Access Control and Toll Systems

In today’s fast-paced world, vehicle identification needs to be quick, secure, and contactless. An RFID Tag on the Windscreen provides exactly that — a reliable way to manage toll collection, parking, and gated access without stopping vehicles.

Tags

RELATED BLOGS

RFID in Logistics: How to Eliminate RFID Misrouting and RFID Label Failures

RFID in logistics is more than just a tool to speed up processes. It has become a key part of how modern supply chains operate.

What Is RFID Waste Management

Imagine a city where every trash bin speaks — not literally — but through a tiny chip that tells the system when it’s full, when it’s emptied, and where it went. That’s what RFID waste management is doing today.

What are Bolt Seals and their Applications? | Complete Guide

In global trade and logistics, bolt seals play a crucial role in ensuring cargo security and compliance. These small but powerful devices are designed to lock shipping containers, trailers, and cargo doors with a tamper-evident mechanism.