金属表面上の RFID タグはどのように機能するのでしょうか?

目次

オンメタルRFIDタグ:その仕組みと産業バイヤーが必要とする理由

標準的なRFIDタグが金属表面で苦戦する理由

標準的なRFIDタグは、費用対効果が高く、広く使用されていますが、金属表面で確実に動作するようには設計されていません。通常のRFIDタグで金属製の機器、工具、コンテナにタグを付けようとして、読み取り失敗や不安定なパフォーマンスを経験しているのはあなただけではありません。なぜこのようなことが起こるのかを説明します:

1.信号の反射と干渉

RFIDリーダーから放射された電波は金属表面で跳ね返り、マルチパス干渉を引き起こします。これは、信号が予測不可能に散乱し、RFIDリーダーを混乱させ、その結果生じることを意味する:

- 読み逃した本

- タグの重複読み取り

- 読み取り精度の低下

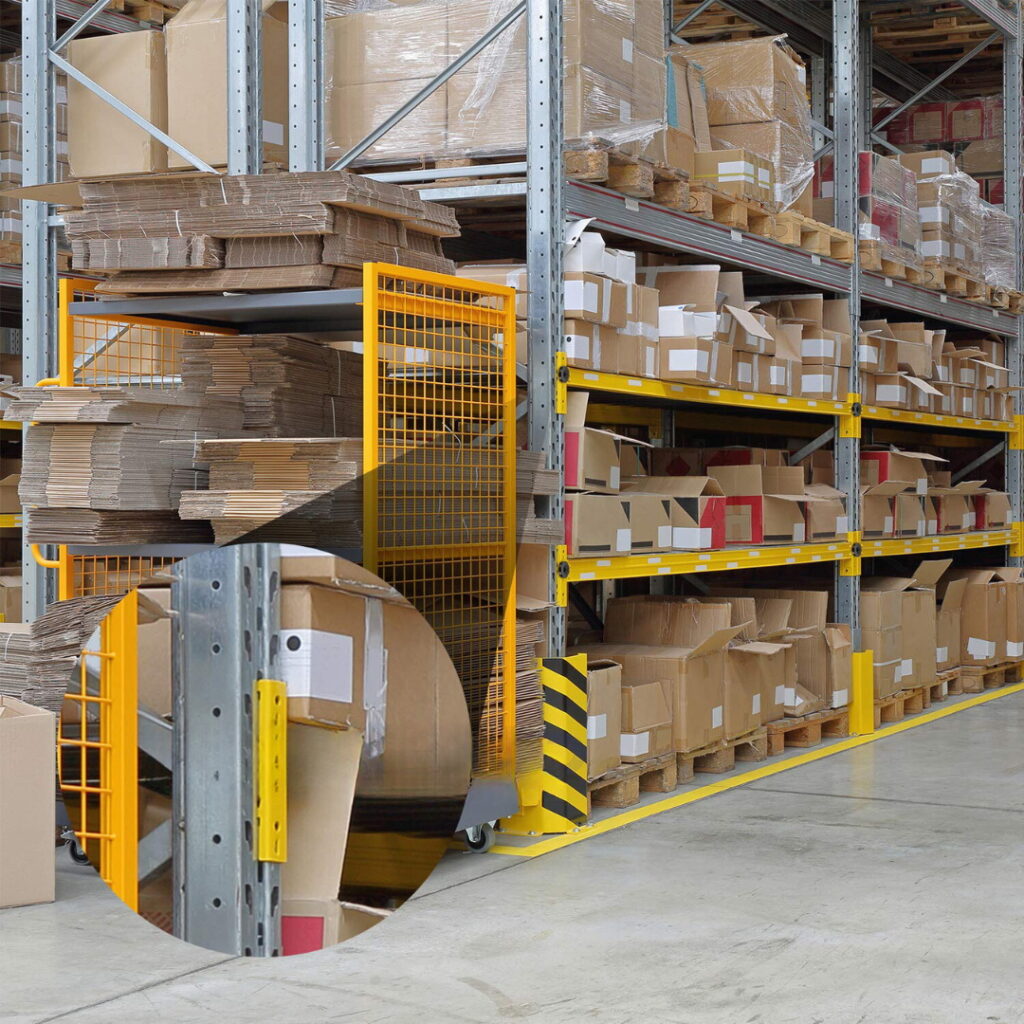

例倉庫では、金属ラックに積まれた製品をスキャンすると、信号の反射により読み取り値が一定しないことがあります。

2.アンテナのデチューニング

RFIDタグは、特定の周波数(UHFやHFなど)で共振するように設計されたアンテナを含んでいる。タグが金属の上に置かれると、導電性の表面は電磁場を変化させ、アンテナの同調を解除し、タグを無効にしてしまう。

これは次のことにつながる:

- 完全な信号損失

- タグから読み取り機への通信不良

- 読み取り範囲の大幅な縮小

例えるなら:間違った周波数にチューニングされたラジオを使うようなものだ。

3.パッシブタグにおける電力消耗

パッシブRFIDタグは、チップに電力を供給しデータを送り返すために、RFIDリーダーの信号からのエネルギーに依存している。しかし、金属表面はこのエネルギーを吸収または偏向するため、タグは機能するのに十分な電力を得られません。

その結果、こうなる:

- タグがアクティブにならない

- 部分的なデータ転送

- ミッションクリティカルなアプリケーションにおけるタグ寿命の短縮

影響大型の金属製機械や金属製包装のある産業環境では、パッシブタグは適切にシールドされない限り、しばしば故障する。

4.一貫性のない読み取りゾーン

標準的なRFIDタグを金属の近くや金属上で使用する場合:

- リードゾーンが予測不能に

- タグはあるポジションでは機能するが、他のポジションでは機能しない

- システムの信頼性が低下し、オペレータをイライラさせ、ワークフローを遅延させる。

結論リアルタイムの追跡と在庫の可視化をRFIDに依存している場合、標準的な金属タグは運用の正確さとROIを損ないます。

金属上 RFID タグとは何ですか?

オンメタルRFIDタグ(アンチメタルRFIDタグまたはメタルマウントRFIDタグとも呼ばれる)は、従来のRFIDタグでは信頼できなかった金属表面上または金属表面付近で効果的に動作するように設計された特別設計のRFIDトランスポンダです。

これらのタグは、通常のRFIDタグを少し改良しただけのものではなく、金属による干渉を克服するために、高度な材料と設計戦略を用いて専用に作られている。

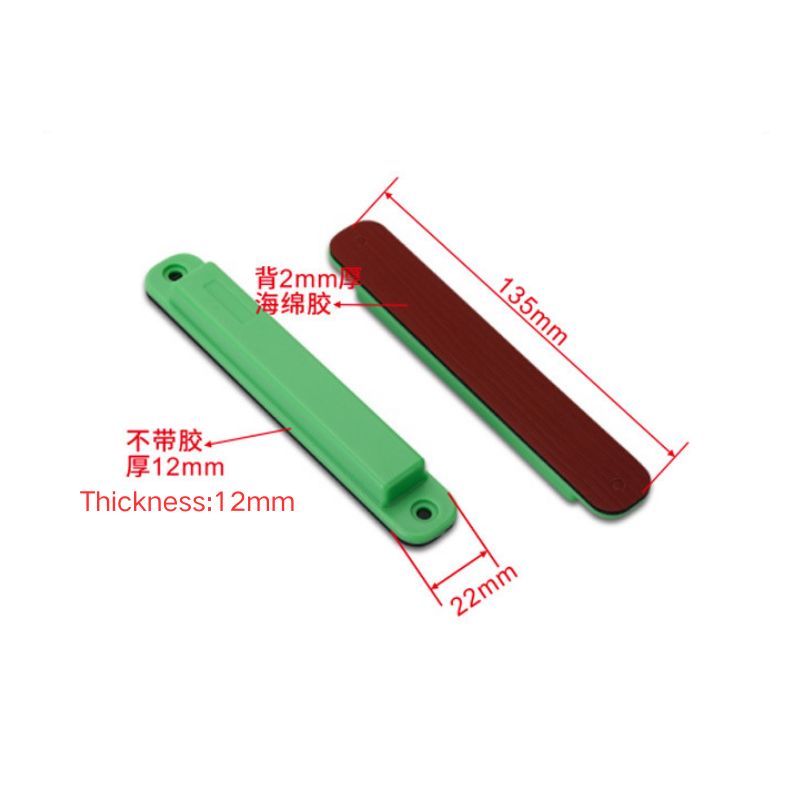

製造方法

金属で機能するために、これらのタグは組み込まれている:

絶縁層:RFIDアンテナとチップを金属表面から分離し、離調を防ぐ。

フェライトの裏打ち:電磁界をリダイレクトする磁性層で、クリーンな信号伝送を可能にする。

最適化されたアンテナ:導電性表面を持つニアフィールド環境用に明確に設計されています。

耐久性のあるハウジング:ABS、エポキシ、金属ケーシングのような素材は、振動、ほこり、油、湿気などの工業的乱用からタグを保護します。

これらのコンポーネントは、金属製の工具、機械、車両、またはコンテナに直接取り付けられた場合でも、タグが確実にデータを送信するように連携しています。

デザイン・バリエーション

オンメタルRFIDタグは、お客様の運用ニーズに合わせて、以下のようなさまざまな形状やサイズがあります:

- 金属製の棚やコンテナに表面実装するための平らなタグ。

- パイプや円筒形機器用のカーブまたはフレキシブルタグ。

- 工具や金属資産に埋め込むための頑丈なコインタグ。

- 発泡スチロールを使用したラベルで、費用対効果が高く、1回限りの使用に適しています。

詳細を見る オンメタルRFIDタグ製品ライン

オンメタルRFIDタグの仕組み:干渉を克服するエンジニアリング

RFID技術は、電波を介したリーダーとタグの間の円滑な通信に依存している。しかし、タグがそのような条件下で機能するように特別に設計されていない限り、金属が環境中に持ち込まれると、この通信は中断される。

オンメタルRFIDタグはまさにそのために作られている。

核心への挑戦電磁場を乱す金属

標準的なRFIDシステムでは、タグ内部のアンテナは特定の周波数(通常はUHFまたはHF)で共振する。金属の上に置くと

- アンテナの共振周波数が変わる(デチューニング)

- 無線信号が予測不可能に吸収または反射される

- リーダとタグ間の通信が不安定になるか、完全に中断される。

オンメタルRFIDタグは、これらの課題を克服するために多層設計を採用している。

標準RFIDタグとオンメタルRFIDタグの主な要点

| 特徴 | 標準RFIDタグ | オンメタルRFIDタグ |

| 金属表面への作用 | ❌ 故障または信号が弱い | 金属用に設計された ✅ 金属用に設計された |

| 金属に近い範囲を読む | 著しく低下した | 最大 10 メートル (UHF) |

| 干渉への耐性 | 信頼できない | フェライト・バック・シールド |

| 過酷な環境下での耐久性 | ⚠️ リミテッド | IP67+ 認証素材 |

正しいタグの選択にお困りですか?

JIA RFIDのエンジニアリングチームは、産業界のお客様に無料のコンサルティングとカスタムソリューションを提供しています。重機械、コンテナ、または過酷な環境にある機器を追跡する場合、最適な製品をご提案いたします。

オンメタルRFIDタグの産業応用

オンメタルRFIDタグは、金属製の工具、部品、構造物、機器に依存する業界にとって画期的な製品です。従来のタグとは異なり、精度、耐久性、リアルタイムのデータが不可欠な、頑丈で金属を多用する環境向けに作られています。

JIA RFIDのファクトリーダイレクトオンメタルタグがオペレーションを改善し、コストを削減し、トレーサビリティを強化している主な産業と実際のアプリケーションを以下に示す。

1.製造・産業機器

使用例:

- 製造現場での工具、金型、治具の追跡

- ステーション間を移動する仕掛品(WIP)の監視

- メンテナンス・スケジューリングのための金属機械の特定

メリットだ:

ツールのアカウンタビリティを確保し、生産の遅れを減らし、リアルタイムの可視性によって予防保守をサポートします。

関連商品 RFIDディスク&コイン・タグ

2.物流・倉庫

使用例:

- 金属製輸送コンテナ、パレット、木箱の管理。

- 返品可能な輸送品目(RTI)の追跡。

- ハンドヘルドリーダーによるゲートイン・ゲートアウトスキャンの自動化。

メリットだ:

手作業によるスキャンが不要になり、資産のロスを減らし、一括読み取り機能により在庫監査をスピードアップ。

関連商品 ハンドヘルドRFIDリーダー

3.石油・ガス

使用例:

- 金属パイプ、バルブ、フランジの識別と追跡

- 海洋リグでの掘削装置の監視

- 検査および認証記録の管理

メリットだ:

バーコードラベルが機能しない腐食性高温環境において、安全コンプライアンスと資産のトレーサビリティを向上させます。

RFIDが勝つ理由: オンメタルタグは、一般的な追跡ラベルを劣化させる水、圧力、化学薬品に耐性があります。

4.航空宇宙

使用例:

- 航空機部品と構造部品の追跡

- 格納庫での工具や校正機器の管理

- MRO(メンテナンス、修理、オーバーホール)文書の自動化

メリットだ:

ミッションクリティカルなコンポーネントのトレーサビリティを向上させるとともに、安全性が重視される環境における事務処理と人的ミスを削減します。

ボーナスだ: メタルセーフRFIDタグは航空グレードの要件を満たし、振動や圧力の変動に耐える。

5.建設・インフラ

使用例:

鉄骨梁、足場、金属製備品にタグを付ける

高価な工具やモバイル機器の追跡

建築部材の検査記録

メリットだ:

備品の紛失を減らし、工具の滞留を防ぎ、現場の安全基準を確実に遵守します。

6.IT資産管理とデータセンター

使用例:

メタルサーバーとネットワーク機器のラベリングと棚卸し

バックアップ・ドライブ、ラック、モバイル・カートの保護

ハンドヘルドRFIDスキャンで監査をサポート

メリットだ:

コンプライアンス・レポーティングを迅速化し、手作業によるミスを最小限に抑え、高密度のサーバールームにおける資産のトレーサビリティをサポートします。

で強化する: データセンター用RFIDリーダー

金属資産に大規模なタグ付けを行う準備はできていますか?

JIA RFIDはバルク価格、サンプルキット、カスタムソリューションを提供し、どんなに厳しい条件でもお客様のアプリケーションに適合します。

なぜJIA RFIDから購入するのか?

工場直販メーカーとして、JIA RFIDは以下を提供します:

- ユニークな金属表面のカスタム設計サポート

- 競争力のある一括価格と迅速なリードタイム

- B2B顧客向けグローバル配送

- 特殊環境向けの社内エンジニアリング

RFIDタグの種類をもっと見る

🔹 RFIDディスク&コインタグ

🔹 ハンドヘルド RFID リーダー

製品ハイライトオンメタルRFIDタグの特徴

- 周波数UHF(860-960MHz)またはHFオプション

- 読み取り範囲最大10メートル(UHF)

- IP等級IP67+ 産業環境用

- 取り付けオプション接着剤、ネジ、リベット

よくある質問

RFIDタグは本当に金属の上で機能するのか?

はい。オンメタルRFIDタグは金属干渉に対応するように設計されているため、金属製の工具、機械、設備にタグを付けるのに理想的です。

オンメタルRFIDタグの価格は?

価格はタイプと数量によって異なる。パッシブバージョンの場合、バルク価格はタグ1枚あたり$0.50からです。お客様の業種に合わせたお見積もりをいたします。

RFIDタグは防水性、耐熱性がありますか?

はい、当社のオンメタルRFIDタグの多くはIP67+規格に適合しており、過酷な産業環境での使用を想定して設計されています。

購入前にテストできますか?

もちろんです。適格なプロジェクトには無料サンプルを提供しています。評価サポートについてはお問い合わせください。

コメント

人気商品

物流におけるRFID:RFID誤配送とRFIDラベル故障の解消方法

物流におけるRFIDは、単にプロセスを迅速化するツール以上の存在である。現代のサプライチェーンが機能する上で、その重要な要素となっている。.

RFID廃棄物管理とは何か

想像してみてください。街中のゴミ箱がすべて「話す」街を――文字通りではなく――小さなチップを通じて、満杯になった時、空になった時、そしてどこへ運ばれたかをシステムに伝えるのです。それが今日のRFID廃棄物管理の仕組みです。.

ボルトシールとその用途とは?| 完全ガイド

世界的な貿易と物流において、ボルトシールは貨物のセキュリティとコンプライアンスを確保する上で重要な役割を果たしています。これらの小型で強力なデバイスは、タンパーエビデント機構で輸送コンテナ、トレーラー、貨物ドアをロックするように設計されています。

RFIDカードプロテクターとは?メリット、使用例、購入ガイド

RFID(Radio Frequency Identification)テクノロジーは、クレジットカード、IDバッジ、定期券、ホテルのルームキーなど、あらゆるところに浸透している。RFIDはスピードと利便性を提供する一方で、「スキミング」と呼ばれる新たなデジタル窃盗への扉も開いている。そこでRFIDカードプロテクターの出番です。

イベント用RFIDリストバンド:主催者向け一括購入ガイド

イベント用RFIDリストバンドは、コンサート、フェスティバル、スポーツ会場などで、迅速な入場、不正防止、キャッシュレス決済を必要とする主催者にとって、最適なソリューションになりつつあります。紙のチケットやQRコードとは異なり、これらのスマートリストバンドは埋め込みチップを使用し、アクセスを合理化し、取引を安全にし、ゲストの体験を向上させます。

フロントガラス上のRFIDタグが車両入退場管理と料金システムを改善する方法

ペースの速い今日の世界では、車両識別は迅速、安全、非接触である必要があります。フロントガラス上のRFIDタグは、まさにそれを提供します-車両を止めることなく、料金徴収、駐車、ゲートアクセスを管理する信頼性の高い方法です。

タグ

関連ブログ

物流におけるRFID:RFID誤配送とRFIDラベル故障の解消方法

物流におけるRFIDは、単にプロセスを迅速化するツール以上の存在である。現代のサプライチェーンが機能する上で、その重要な要素となっている。.

RFID廃棄物管理とは何か

想像してみてください。街中のゴミ箱がすべて「話す」街を――文字通りではなく――小さなチップを通じて、満杯になった時、空になった時、そしてどこへ運ばれたかをシステムに伝えるのです。それが今日のRFID廃棄物管理の仕組みです。.

ボルトシールとその用途とは?| 完全ガイド

世界的な貿易と物流において、ボルトシールは貨物のセキュリティとコンプライアンスを確保する上で重要な役割を果たしています。これらの小型で強力なデバイスは、タンパーエビデント機構で輸送コンテナ、トレーラー、貨物ドアをロックするように設計されています。