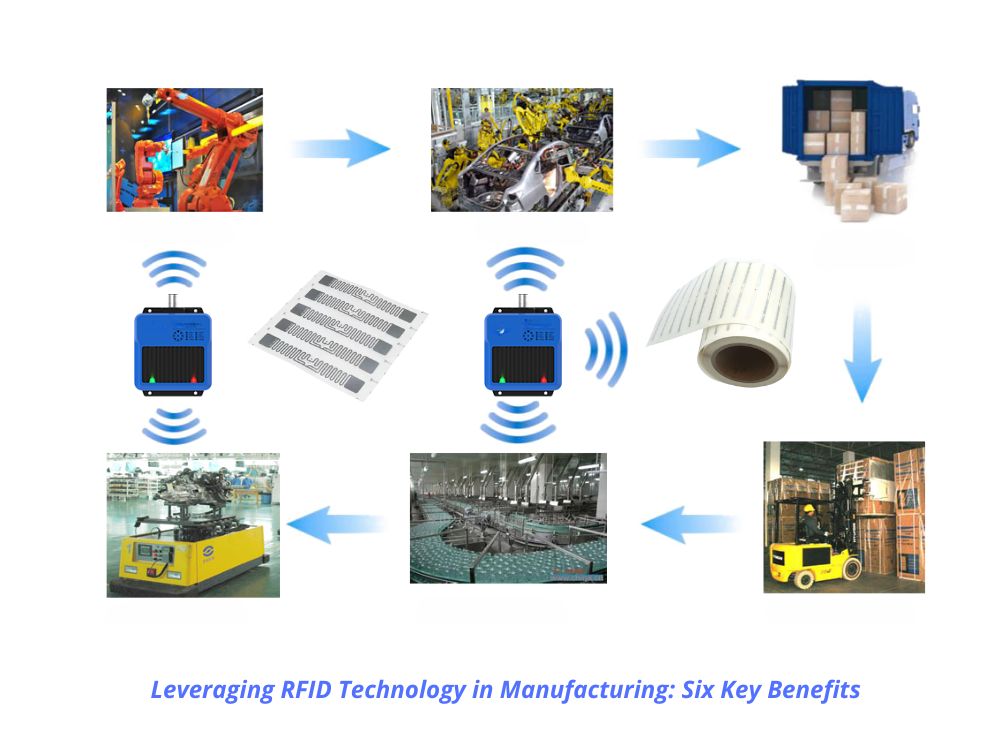

Leveraging RFID Technology in Manufacturing: Six Key Benefits

Table of Contents

Summary

As manufacturing environments become more complex, the integration of RFID systems provides a solution to common challenges such as inventory management, production control, and quality assurance. This article explores six significant ways RFID technology can enhance manufacturing operations.

Enhanced Production Control

RFID technology significantly improves control over manufacturing processes by providing real-time visibility of various components and materials. From raw materials and sub-assemblies to machine tools and bulk containers, RFID tags ensure that every item is tracked and monitored throughout the production cycle.

Real-Time Tracking and Visibility

RFID systems enable manufacturers to ascertain the physical location of items at any given moment. For instance, Syngenta, a chemicals manufacturer, integrates RFID with its ERP system to track ingredient bags across multiple plants, thereby enhancing production efficiency and accuracy.

Aspect | RFID-Enabled Control |

Items Tracked | Raw materials, sub-assemblies, tools |

Visibility | Real-time location and status updates |

Example | Syngenta’s tracking of ingredient bags |

Improved Quality Assurance

RFID tags contribute to higher product quality by ensuring correct material handling and adherence to production sequences. By attaching RFID tags to components, manufacturers can align materials with specific production requirements, reducing errors and ensuring consistency.

Reducing Manufacturing Errors

At Ulster Carpets, RFID tags are affixed to bobbins, linking them to a database that matches yarns to be woven. This process minimizes costly manufacturing errors and ensures that the correct materials are used at each stage of production.

Optimized Resource Usage

RFID technology can significantly reduce waste and energy consumption by automating machinery operations and material usage. Intelligent systems powered by RFID can manage resources more effectively, leading to cost savings and environmental benefits.

Efficient Energy Management

At Vaillant’s boiler manufacturing plant, RFID readers detect the arrival of chassis at specific stations, powering up tools only when needed. Similarly, MX Group uses RFID to accurately measure resin quantities for each mould, optimizing raw material usage and reducing waste.

Application | RFID Optimization |

Energy Management | Automated tool activation based on presence |

Material Usage | Precise resin measurement for moulds |

Examples | Vaillant and MX Group |

Ensuring Product Authenticity and Traceability

RFID systems are invaluable for verifying product authenticity and maintaining traceability. By embedding RFID tags in products, manufacturers can track each item’s history and ensure its legitimacy.

Counterfeit Prevention

In motor racing, RFID tags embedded in vehicle panels are scanned by officials to confirm that only authorized panels are used. This practice prevents counterfeit parts from entering the market, safeguarding both safety and fairness in the sport.

Efficient Management of Repairs and Returns

RFID technology simplifies the management of repairs and warranty claims by providing detailed information on product history and previous issues. This data aids in validating claims and identifying recurring problems.

Monitoring Warranty Claims

RFID systems can track the age of products and previous repair incidents. This capability helps in assessing warranty claims and identifying persistent faults, allowing manufacturers to address common issues effectively.

Enhanced Data Insights for Improved Efficiency

RFID systems provide comprehensive data that enhances operational efficiency and asset management. Continuous data updates enable manufacturers to gain accurate insights into their processes, leading to improved decision-making and cost reduction.

Data-Driven Decision Making

The automatic updating of databases with RFID technology provides valuable insights into production processes and asset usage. This detailed data helps manufacturers optimize operations, reduce costs, and enhance overall performance.

Benefit | Impact of RFID Data Insights |

Operational Efficiency | Enhanced asset management and usage |

Cost Reduction | Improved decision-making and performance |

Example | Continuous data updates and insights |

Conclusion

RFID technology offers substantial benefits for manufacturers by improving production control, quality assurance, resource usage, authenticity verification, repair management, and data insights. By integrating RFID systems into their operations, manufacturers can achieve greater efficiency, reduce costs, and enhance overall productivity. The application of RFID in these areas demonstrates its critical role in advancing modern manufacturing practices.

Comments

Hot Products

RFID in Logistics: How to Eliminate RFID Misrouting and RFID Label Failures

RFID in logistics is more than just a tool to speed up processes. It has become a key part of how modern supply chains operate.

What Is RFID Waste Management

Imagine a city where every trash bin speaks — not literally — but through a tiny chip that tells the system when it’s full, when it’s emptied, and where it went. That’s what RFID waste management is doing today.

What are Bolt Seals and their Applications? | Complete Guide

In global trade and logistics, bolt seals play a crucial role in ensuring cargo security and compliance. These small but powerful devices are designed to lock shipping containers, trailers, and cargo doors with a tamper-evident mechanism.

What is an RFID Card Protector? Benefits, Use Cases, and Buying Guide

RFID technology (Radio Frequency Identification) is everywhere: in your credit cards, ID badges, transit passes, hotel room keys, and more. It offers speed and convenience, but it also opens the door to a new kind of digital theft called “skimming.” That’s where an RFID card protector comes in.

RFID Wristbands for Events: Bulk Buying Guide for Organizers

RFID wristbands for events are becoming the go-to solution for organizers who need faster entry, fraud prevention, and cashless payments at concerts, festivals, and sports venues. Unlike paper tickets or QR codes, these smart wristbands use embedded chips to streamline access, secure transactions, and improve the guest experience.

How RFID Tag on Windscreen Improves Vehicle Access Control and Toll Systems

In today’s fast-paced world, vehicle identification needs to be quick, secure, and contactless. An RFID Tag on the Windscreen provides exactly that — a reliable way to manage toll collection, parking, and gated access without stopping vehicles.

Tags

RELATED BLOGS

RFID in Logistics: How to Eliminate RFID Misrouting and RFID Label Failures

RFID in logistics is more than just a tool to speed up processes. It has become a key part of how modern supply chains operate.

What Is RFID Waste Management

Imagine a city where every trash bin speaks — not literally — but through a tiny chip that tells the system when it’s full, when it’s emptied, and where it went. That’s what RFID waste management is doing today.

What are Bolt Seals and their Applications? | Complete Guide

In global trade and logistics, bolt seals play a crucial role in ensuring cargo security and compliance. These small but powerful devices are designed to lock shipping containers, trailers, and cargo doors with a tamper-evident mechanism.