RFID Revolutionizing the Manufacturing Industry

Table of Contents

Introduction

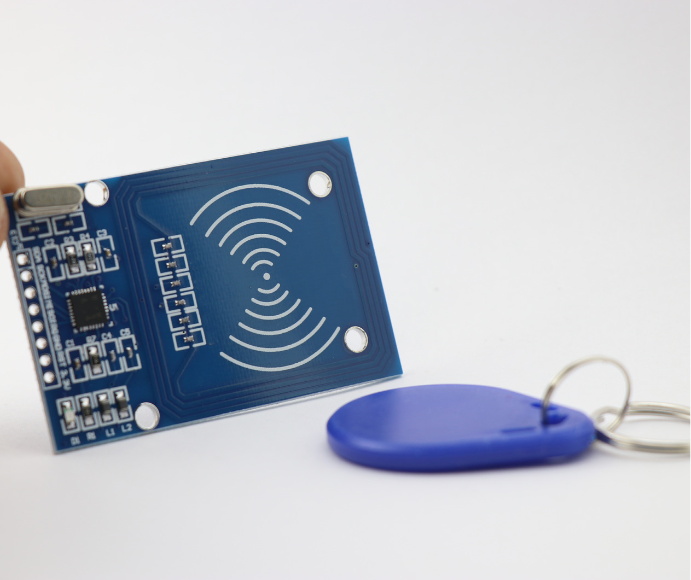

From automotive to pharmaceuticals, RFID is proving to be a game-changer, not only in supply chain management but also in the production floor and inventory management. This article explores the significant ways RFID is revolutionizing manufacturing.

RFID in Production Processes

Enhancing Efficiency in Harsh Environments

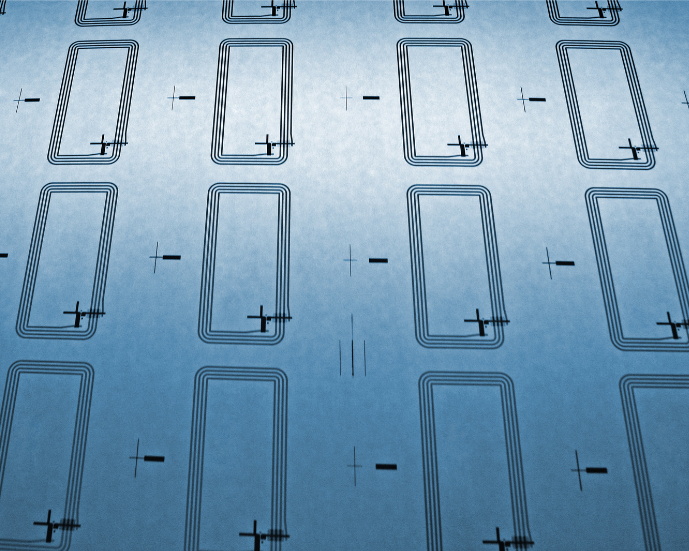

Manufacturing environments often involve extreme conditions such as high temperatures, humidity, and exposure to chemicals. RFID systems designed to withstand these harsh conditions are invaluable in controlling and monitoring operations. For instance, RFID tags can store vast amounts of data, allowing manufacturers to optimize their production processes.

Flexibility in Assembly Line Production

In industries like automotive manufacturing, RFID provides flexibility in assembly line processes. By tagging machines, conveyors, and raw materials, manufacturers can monitor real-time movements, leading to more efficient production planning. RFID technology also enables the tracking of equipment within the facility, improving overall operational efficiency.

Application Area | Benefits of RFID |

Production Monitoring | Real-time tracking and data storage for optimized processes |

Equipment Tagging | Enhanced monitoring of machinery and tools |

Raw Material Tracking | Efficient production planning with real-time visibility |

RFID in the Supply Chain

Improving Supply Chain Efficiency

RFID technology plays a crucial role in enhancing the accuracy and reliability of supply chain operations. By providing real-time visibility of materials and assets, RFID ensures that the manufacturing process operates seamlessly. This technology reduces shipping errors, improves security, and validates both raw materials and finished goods.

Real-Time Visibility

One of the significant advantages of RFID in the supply chain is its ability to offer real-time visibility. This capability allows manufacturers to track goods throughout the supply chain, reducing delays and improving overall efficiency.

RFID in Inventory Management

Accuracy in Inventory Control

Inventory accuracy is vital in manufacturing, and RFID technology greatly improves this aspect. By tracking products and equipment in real time, RFID enables manufacturers to predict their needs more accurately. This reduces human intervention and minimizes errors in inventory management.

Reducing Shrinkage and Wastage

RFID also helps in reducing resource wastage by providing precise tracking of materials. This ensures that inventory levels are maintained efficiently, reducing the need for reordering materials that are mistakenly considered lost.

Real-World Applications of RFID in Manufacturing

Microcomputer Assembly

A microcomputer assembly company implemented RFID for inventory control and product traceability. The benefits included cost reductions in component substitution and decreased lead times, showcasing the efficiency that RFID brings to manufacturing.

Automotive Manufacturing

General Motors (GM) uses RFID tags on cylinder heads and engine blocks to track each manufacturing process. This enables immediate detection of any errors, ensuring high-quality production standards.

Paper Manufacturing

Kabel Premium Pulp & Paper integrated RFID into their production process to monitor and track each production step. This application of RFID technology allows for continuous oversight of production, leading to improved efficiency.

Semiconductor Manufacturing

Semiconductor companies have adopted RFID in their clean rooms to enhance quality control and operator efficiency. This technology has increased equipment usage and streamlined manufacturing processes.

Conclusion

RFID technology is revolutionizing the manufacturing industry by providing solutions that enhance efficiency, accuracy, and cost-effectiveness. From production monitoring to supply chain management, RFID offers unparalleled advantages. As the technology continues to evolve, its applications in manufacturing are expected to expand further, unlocking new possibilities and innovations.

Comments

Hot Products

RFID in Logistics: How to Eliminate RFID Misrouting and RFID Label Failures

RFID in logistics is more than just a tool to speed up processes. It has become a key part of how modern supply chains operate.

What Is RFID Waste Management

Imagine a city where every trash bin speaks — not literally — but through a tiny chip that tells the system when it’s full, when it’s emptied, and where it went. That’s what RFID waste management is doing today.

What are Bolt Seals and their Applications? | Complete Guide

In global trade and logistics, bolt seals play a crucial role in ensuring cargo security and compliance. These small but powerful devices are designed to lock shipping containers, trailers, and cargo doors with a tamper-evident mechanism.

What is an RFID Card Protector? Benefits, Use Cases, and Buying Guide

RFID technology (Radio Frequency Identification) is everywhere: in your credit cards, ID badges, transit passes, hotel room keys, and more. It offers speed and convenience, but it also opens the door to a new kind of digital theft called “skimming.” That’s where an RFID card protector comes in.

RFID Wristbands for Events: Bulk Buying Guide for Organizers

RFID wristbands for events are becoming the go-to solution for organizers who need faster entry, fraud prevention, and cashless payments at concerts, festivals, and sports venues. Unlike paper tickets or QR codes, these smart wristbands use embedded chips to streamline access, secure transactions, and improve the guest experience.

How RFID Tag on Windscreen Improves Vehicle Access Control and Toll Systems

In today’s fast-paced world, vehicle identification needs to be quick, secure, and contactless. An RFID Tag on the Windscreen provides exactly that — a reliable way to manage toll collection, parking, and gated access without stopping vehicles.

Tags

RELATED BLOGS

RFID in Logistics: How to Eliminate RFID Misrouting and RFID Label Failures

RFID in logistics is more than just a tool to speed up processes. It has become a key part of how modern supply chains operate.

What Is RFID Waste Management

Imagine a city where every trash bin speaks — not literally — but through a tiny chip that tells the system when it’s full, when it’s emptied, and where it went. That’s what RFID waste management is doing today.

What are Bolt Seals and their Applications? | Complete Guide

In global trade and logistics, bolt seals play a crucial role in ensuring cargo security and compliance. These small but powerful devices are designed to lock shipping containers, trailers, and cargo doors with a tamper-evident mechanism.