The Smart Applications of Passive RFID Tags: A Technological Perspective

Table of Contents

Summary

As a cornerstone of modern inventory and tracking systems, these tags have enabled businesses to streamline operations and reduce errors. This article delves into the technical aspects of passive RFID tags, their working principles, and their applications across industries.

Understanding Passive RFID Tags

RFID Tags Overview

RFID (Radio Frequency Identification) technology is a method of identifying and tracking objects using radio waves. An RFID system typically comprises three components: tags, readers, and antennas. Tags are further classified into passive, active, and semi-active types based on their power source.

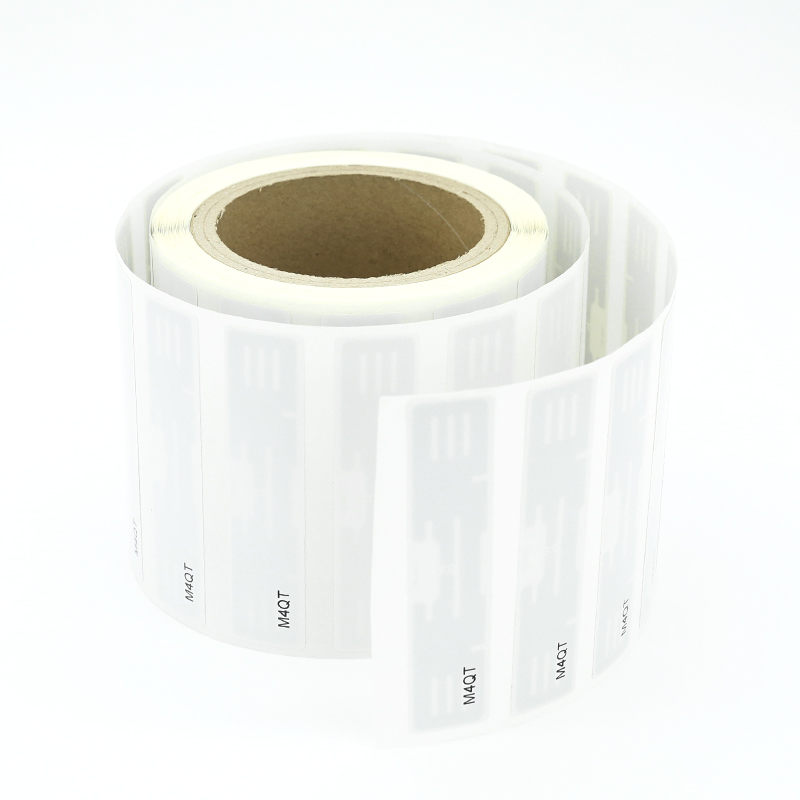

Passive RFID Tags

Passive RFID tags operate without an internal power supply, drawing energy from the electromagnetic field emitted by an RFID reader. This characteristic makes them compact, cost-effective, and long-lasting. Unlike active tags, which contain a battery and can transmit signals over longer distances, passive tags are limited to shorter ranges but are preferred for applications requiring low cost and minimal maintenance.

Type of RFID Tag | Power Source | Range | Cost | Maintenance |

Passive | No internal power | Short (centimeters to meters) | Low | Minimal |

Active | Battery-powered | Long (up to hundreds of meters) | High | Higher due to battery replacement |

Semi-active | Battery-assisted | Medium | Moderate | Moderate |

Working Principle of Passive RFID Tags

The operational mechanism of passive RFID tags is straightforward yet highly efficient. When a reader emits radio frequency signals, the tag’s antenna captures these signals and converts them into electrical energy. This energy activates the chip within the tag, which then reflects the stored information back to the reader. The simplicity of this process gives passive RFID tags several advantages:

- Low Cost:Their simple construction allows for large-scale production at a low cost.

- Long Lifespan:Without a battery, these tags can function for extended periods with negligible maintenance.

Versatility in Form Factor: Their small size and flexible shapes allow them to be used in various environments.

Key Applications of Passive RFID Tags

Logistics and Supply Chain Management

In logistics and supply chain operations, passive RFID tags are instrumental in real-time tracking and inventory management. By affixing tags to items, companies can monitor the location and condition of goods throughout the supply chain. This leads to increased efficiency, reduced errors, and optimized transportation.

Warehouse Automation

Warehouse operations benefit from the automation provided by passive RFID systems. Inventory counts can be conducted swiftly, and data can be automatically updated, eliminating manual entry errors.

Retail Industry

Retailers utilize passive RFID tags to enhance inventory accuracy, streamline checkout processes, and improve security. By tagging merchandise, retailers can gain real-time insights into stock levels and movement patterns.

Enhancing the Consumer Experience

Self-service checkout stations use passive RFID technology to simplify the shopping process. Additionally, anti-theft systems based on RFID tags bolster security measures.

Healthcare Sector

Hospitals and medical facilities use passive RFID tags to monitor patient locations, manage medical equipment, and track medication. By tagging assets and patients, healthcare providers can ensure accuracy and safety.

Medication Management

Passive RFID tags are invaluable in tracking medications, ensuring that drugs are stored and dispensed accurately. This helps prevent the distribution of expired or counterfeit medicines.

Transportation and Public Services

In public transportation and infrastructure, passive RFID tags facilitate efficient travel and smart city initiatives. These tags are embedded in public transport cards and urban management systems, enhancing operational efficiency.

Urban Infrastructure

Passive RFID tags enable smart waste management by monitoring trash bin levels, optimizing collection routes, and improving urban cleanliness.

Industrial Manufacturing

In industrial settings, passive RFID tags assist in monitoring production lines, tracking components, and maintaining equipment. These tags ensure precision in manufacturing and reduce downtime through predictive maintenance.

Conclusion

Passive RFID tags have become indispensable across industries, providing cost-effective, reliable, and scalable solutions for tracking and inventory management. Their simplicity, coupled with their ability to integrate seamlessly into existing systems, makes them a key component in the era of the Internet of Things. As technology advances, the applications and capabilities of passive RFID tags will continue to expand, driving innovation and efficiency in both established and emerging sectors.

FAQs on Passive RFID Tags

How Do Passive RFID Tags Compare to Active and Semi-Active Tags?

Passive RFID tags are less expensive and require minimal maintenance compared to active tags. They are ideal for short-range, high-volume applications.

What Should Be Considered When Selecting Passive RFID Tags?

Considerations include environmental conditions, required read range, and tag durability. Selection should align with the specific needs of the application.

Is the Installation of Passive RFID Tags Complex?

Installation is generally straightforward, requiring basic setup without specialized tools. Regular maintenance involves ensuring that tags remain intact and functional within their environment.

Comments

Hot Products

RFID in Logistics: How to Eliminate RFID Misrouting and RFID Label Failures

RFID in logistics is more than just a tool to speed up processes. It has become a key part of how modern supply chains operate.

What Is RFID Waste Management

Imagine a city where every trash bin speaks — not literally — but through a tiny chip that tells the system when it’s full, when it’s emptied, and where it went. That’s what RFID waste management is doing today.

What are Bolt Seals and their Applications? | Complete Guide

In global trade and logistics, bolt seals play a crucial role in ensuring cargo security and compliance. These small but powerful devices are designed to lock shipping containers, trailers, and cargo doors with a tamper-evident mechanism.

What is an RFID Card Protector? Benefits, Use Cases, and Buying Guide

RFID technology (Radio Frequency Identification) is everywhere: in your credit cards, ID badges, transit passes, hotel room keys, and more. It offers speed and convenience, but it also opens the door to a new kind of digital theft called “skimming.” That’s where an RFID card protector comes in.

RFID Wristbands for Events: Bulk Buying Guide for Organizers

RFID wristbands for events are becoming the go-to solution for organizers who need faster entry, fraud prevention, and cashless payments at concerts, festivals, and sports venues. Unlike paper tickets or QR codes, these smart wristbands use embedded chips to streamline access, secure transactions, and improve the guest experience.

How RFID Tag on Windscreen Improves Vehicle Access Control and Toll Systems

In today’s fast-paced world, vehicle identification needs to be quick, secure, and contactless. An RFID Tag on the Windscreen provides exactly that — a reliable way to manage toll collection, parking, and gated access without stopping vehicles.

Tags

RELATED BLOGS

RFID in Logistics: How to Eliminate RFID Misrouting and RFID Label Failures

RFID in logistics is more than just a tool to speed up processes. It has become a key part of how modern supply chains operate.

What Is RFID Waste Management

Imagine a city where every trash bin speaks — not literally — but through a tiny chip that tells the system when it’s full, when it’s emptied, and where it went. That’s what RFID waste management is doing today.

What are Bolt Seals and their Applications? | Complete Guide

In global trade and logistics, bolt seals play a crucial role in ensuring cargo security and compliance. These small but powerful devices are designed to lock shipping containers, trailers, and cargo doors with a tamper-evident mechanism.