UHF RFID Vehicle Tracking Tire Life Cycle Data Record Tag

Smarter Tire Management with Embedded RFID Technology

Take full control of your vehicle’s tire health and lifecycle data using RFID Vehicle Tracking technology. Designed for fleet operators, tire manufacturers, and automotive OEMs, RFID-enabled tires give you access to real-time tracking of tire wear, pressure, mileage, and maintenance history — helping you reduce downtime, increase safety, and improve operational efficiency.

What Is RFID Tire Tracking?

RFID Vehicle Tracking systems use UHF RFID Tags embedded in or mounted on tires to monitor and log critical tire data throughout its lifecycle. These RFID Vehicle Tracking tags communicate wirelessly with fixed or handheld readers to provide real-time information on:

- Tire ID and origin

- Mileage and service intervals

- Pressure and temperature (if sensor-enabled)

- Retreading cycles and expiration

Key Features & Technical Specifications

| Specification | Details |

| Frequency | UHF (860–960 MHz) |

| Protocol | EPC Gen2 / ISO 18000-6C |

| Chip Type | UCODE 8 / Impinj Monza R6 |

| Tag Format | Embedded inlay or external surface tag |

| Read Range | 3–5 meters (fixed reader) |

| Durability | Vibration, heat, and pressure resistant |

| Mounting Options | Embedded, vulcanized, adhesive |

| Data Retention | 10+ years / 100,000+ cycles |

| Compatibility | Works with standard UHF RFID readers |

How RFID Enhances Tire Lifecycle Management

Traditional tire monitoring relies on manual logging and barcode labels, which are easy to damage or misread.

With RFID:

- Every tire has a unique digital identity

- Data is automatically captured at key points (mounting, replacement, retreading)

- Tire wear and rotation schedules are tracked accurately

- Maintenance staff receive alerts for upcoming servicing or expiration

This results in better resource planning, longer tire lifespan, and fewer failures on the road.

Use Cases of RFID Vehicle Tracking Tags by Industry

Fleet Management & Trucking

- Prevent unexpected tire failures

- Schedule replacements and rotations proactively

- Improve fleet performance metrics with tire-level data

Tire Manufacturers

- RFID tags installed during production

- Enable end-to-end traceability, warranty verification, and anti-counterfeiting

- Meet compliance and quality standards globally

Automotive OEMs

- Integrate tire data with onboard systems (TPMS)

- Improve product performance tracking

- Enable advanced after-sales service data logging

Benefits of RFID Tire Tracking Systems

- Full Tire Lifecycle Traceability — From production to disposal

- Hands-Free Data Capture — Bulk scanning with UHF readers

- ERP/TMS Integration — Syncs with existing fleet and maintenance software

- Anti-Theft & Anti-Counterfeit — Each tire has a secure, tamper-proof ID

- Lower Operating Costs — Extend tire lifespan and reduce blowout incidents

Real-World Example: RFID in a Commercial Fleet

A logistics company managing 2,000+ trucks installed RFID Vehicle Tracking tags across their fleet.

Within 6 months, they achieved:

- 30% reduction in emergency roadside incidents

- 40% faster tire checks during inspection rounds

- 22% increase in average tire lifecycle

- Full integration with their maintenance ERP for alert scheduling

Request a Free Sample or Quote

Need RFID Vehicle Tracking tags for tire lifecycle or fleet tracking?

We’re ready to help you optimize operations with custom UHF RFID tracking tags.

📩 Request a Quote or Free Sample

📱 WhatsApp us now: +86 138 2318 6864

OEM branding | Bulk pricing | Global shipping

Frequently Asked Question

The Top Questions about RFID Vehicle Tracking.

Yes. We offer tag models designed for in-tire mounting, capable of enduring extreme temperature and pressure conditions.

Yes. Our anti-metal RFID tags are built with shielding layers to function on metal or conductive surfaces like chassis or wheel wells.

Use any ISO18000-6C compliant UHF RFID reader—handheld or fixed. Data can be integrated with fleet management, ERP, or logistics software.

Absolutely. We offer EPC memory programming and can preload your IDs or link tags to your vehicle database before shipping.

Hot To Customize RFID Tags

Know the customization process about RFID tags

Size & Shape

Send your requirements on size and shapes. Tags are typically designed in simple shapes and sizes to match the internal antenna. However, they can also be customized in various sizes and shapes to best fit the intended application and the asset being tagged. For instance, RFID hang tags can be customized in size, shape, and attachment method to perfectly suit specific applications.

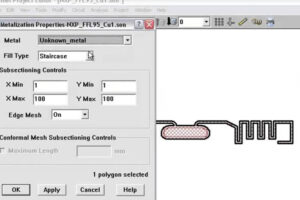

Layout & Chips

In the label format designer, select the layout that matches the type and size of the RFID label you wish to create. Our factory provides a variety of label templates, including RFID-specific options. We also offer a range of RFID chips tailored to meet your specific requirements.

High Customization

Custom tags are designed from the ground up to meet the needs of specific applications, with unique variables for nearly every option listed below. A semi-custom tag typically starts as a standard tag but offers additional customization options, such as custom printing, encoding, or specific backings and attachment methods.

Sample Confirmation

Before proceeding with full-scale production, we offer a sample confirmation process to ensure that the RFID tags meet your exact specifications and application requirements.

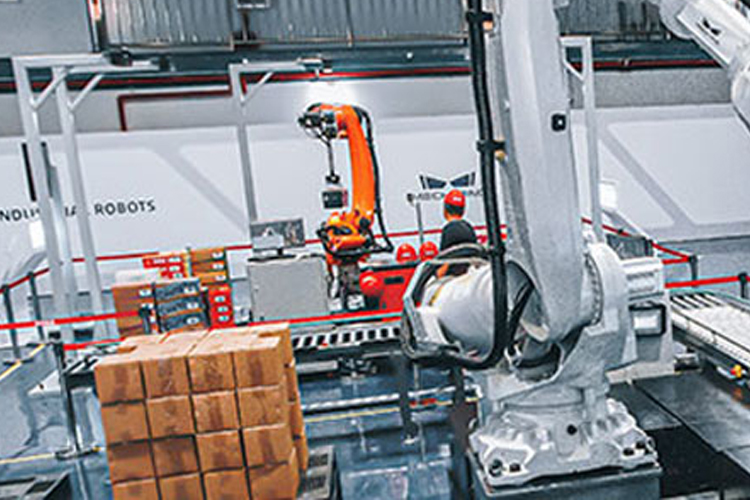

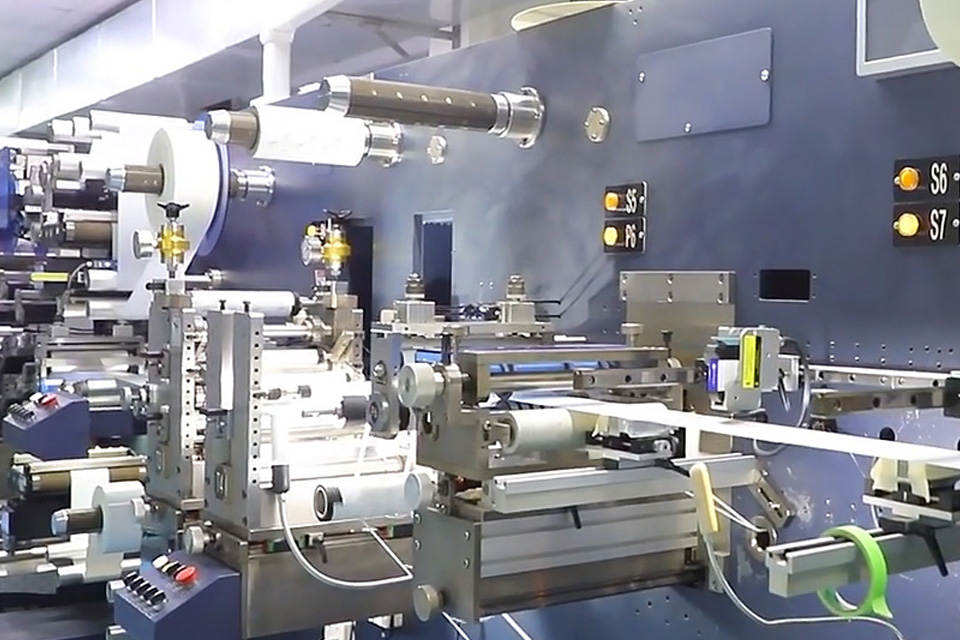

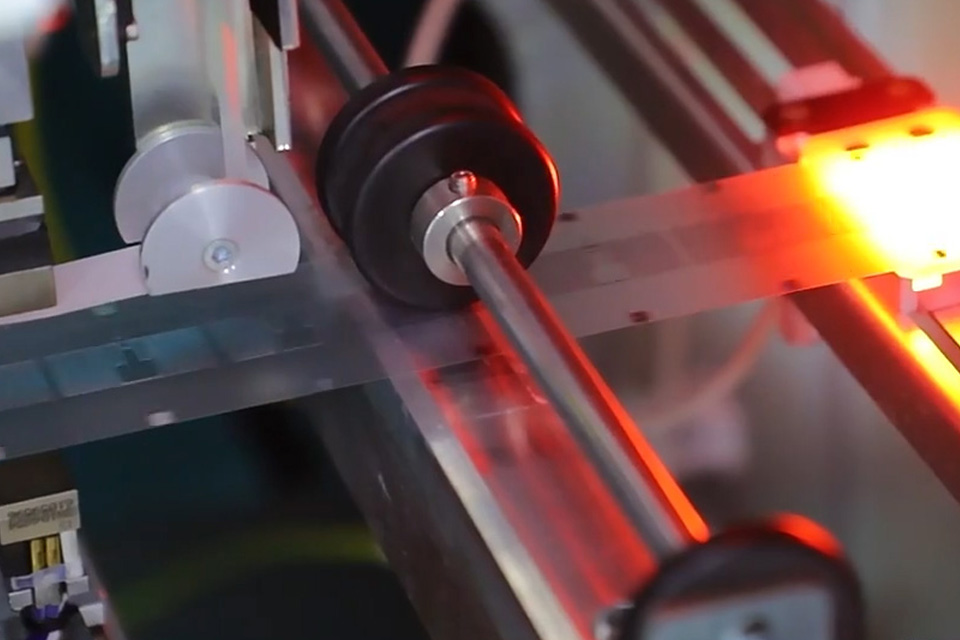

Mass Production

Our mass production process for RFID tags is designed to deliver high-quality, reliable products at scale, ensuring that your business has a steady and consistent supply of RFID solutions tailored to your needs. Leveraging state-of-the-art manufacturing facilities and advanced technology, we maintain efficiency and precision throughout the production cycle.

RFID Tags Application

Use customized RFID tags in different industies.

RFID Vehicle Tags

Vehicles with RFID tags enable secure access to gated areas. RFID tags also streamline truck weighing for efficient billing.

Temperature Sensor Tags

RFID temperature sensors, used in industries like steel, send data to alert users of unsafe conditions via RFID readers.

RFID Supply Chain Tags

RFID tags for supply chain visibility track products, showing when a box, pallet, or container moves from one facility to another.

RFID Personnel Tracking

RFID strengthens access security: employee badges for workspace entry, hotel wristbands for pool access.

RFID Pallet Tracking Tags

Our RFID tags are ideal for tracking pallets and containers, offering durable, low-profile solutions for warehouse management.

Custom RFID Tags & Labels

Our factory supplies custom RFID tags and OEM hardware solutions for unique needs when standard RFID products aren't available.

RFID Laundry Tags

Our RFID laundry tags, with a soft rubber casing, are flexible and durable, surviving 200 wash cycles and 60 bars of pressure.

Industrial RFID Tags

We provide rugged industrial RFID tags and readers for demanding applications. Our tags withstand all weather conditions.

Animal RFID Tags

RFID tags track animals and pets using ear tags or injectable ampoules. Ear tags can be custom-printed and come in various colors.

RFID Asset Tracking

RFID tags for asset tracking, like file servers, rental equipment, streamline inventory, asset management, enabling quick location, tracking.

Consumables RFID Tags

RFID counterfeit tags on consumables, with a reader in the machine, verify authenticity and prevent counterfeit use.

Manufacturing RFID Systems

RFID tags are used on almost all products—apparel, furniture, appliances, and cars—and are crucial for automated manufacturing systems.

Why Choose Us

As an original manufacturer with over 13 years of experience, we specialize in designing and manufacturing passive RFID (NFC, HF, and UHF) tags for applications in inventory, laundry, access control, identification, and industrial automation management.

We are a pioneering leader in RFID technology and smart product solutions. For nearly 20 years, we have been at the forefront of custom RFID and NFC technology, offering innovative solutions in every imaginable form. Our expertise lies in developing and producing RFID/NFC products that are tailored to meet your specific requirements.

As the world’s leading RFID supplier, our factory is passionate about RFID technology. We deliver a wide range of products, including NFC tags, NFC cards, RFID/NFC labels, RFID inlays, various apparel tags, laundry tags, and RFID devices, to clients around the globe. Our RFID products are widely used in marketing campaigns, healthcare monitoring, workforce management, stock control, access control, apparel systems, laundry systems, inventory systems, IoT systems, and security applications.

Our Benefits

We provide products with competitive pricing and reliable quality, backed by an after-sales warranty. Whether you are a distributor, system integrator, or end-user, you will find the right RFID and related products here, ensuring that your company gains tangible benefits.

We have grown into a company with over 200 team members, including a production department, R&D center, sales department, technical support, and after-sales service. Understanding that time is of the essence, we can fulfill customized orders within just 5 days. Our dedicated team of over 100 factory staff ensures a stable supply and fast delivery for all our orders.

Related Products

Customize any types RFID tags from our factory to meet your own requirements.

.jpg)