Understanding the Benefits of RFID Tags in Inventory Management

Table of Contents

Summary

With supply chains becoming increasingly complex, businesses are seeking smarter, more efficient ways to track and manage inventory, reduce manual errors, and improve overall operational efficiency. RFID tags provide a seamless solution by enabling real-time tracking and data capture, thus offering businesses a comprehensive understanding of their inventory dynamics.

Key Benefits of RFID Tags in Inventory Management

RFID tags deliver numerous advantages that can significantly enhance the efficiency and accuracy of inventory management processes. Below are some of the key benefits:

Enhancing Inventory Accuracy

RFID technology allows businesses to capture inventory data in real-time, minimizing the errors typically associated with manual scanning in traditional barcode systems. RFID tags can automatically read data without human intervention, leading to more accurate inventory records.

Improving Inventory Visibility

The ability to monitor inventory status in real time provides businesses with unparalleled transparency. RFID tags enable companies to track the location and quantity of each item, helping to prevent overstocking or stockouts, thereby maintaining optimal inventory levels.

Accelerating Inventory Counting

Traditional inventory counting methods are time-consuming and labor-intensive. RFID tags streamline this process by allowing for rapid scanning of multiple items simultaneously, drastically reducing the time required for inventory counts.

Reducing Labor Costs

By automating the data collection process, RFID systems decrease the need for manual labor. This not only cuts labor costs but also reduces the additional expenses that arise from human errors, leading to further cost savings.

Enhancing Security and Anti-Theft Capabilities

RFID tags contribute to improved security in inventory management. For instance, companies can use RFID technology to monitor the movement of high-value items and prevent unauthorized access, thereby reducing the risk of theft and loss.

Facilitating Data Integration and Analysis

RFID tags generate large volumes of data that can be integrated with a company’s ERP (Enterprise Resource Planning) system. This data-driven approach allows for more in-depth analysis, better demand forecasting, and optimized supply chain processes.

Types of RFID Tags for Inventory Management

When implementing RFID technology in inventory management, understanding the characteristics and types of RFID tags is crucial. The following table summarizes the different types of RFID tags and their key features:

Type of RFID Tag | Power Source | Application | Key Features |

Passive RFID Tags | No internal power source | Large-scale inventory management | Low cost, long lifespan |

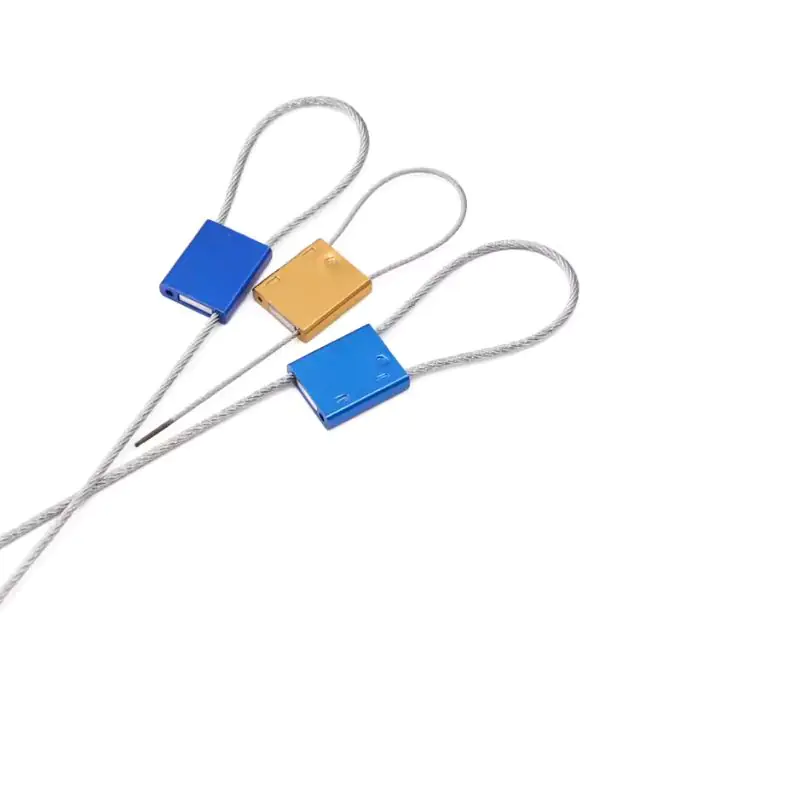

Active RFID Tags | Built-in battery | Large cargo management in warehouses | Long reading distance, real-time tracking |

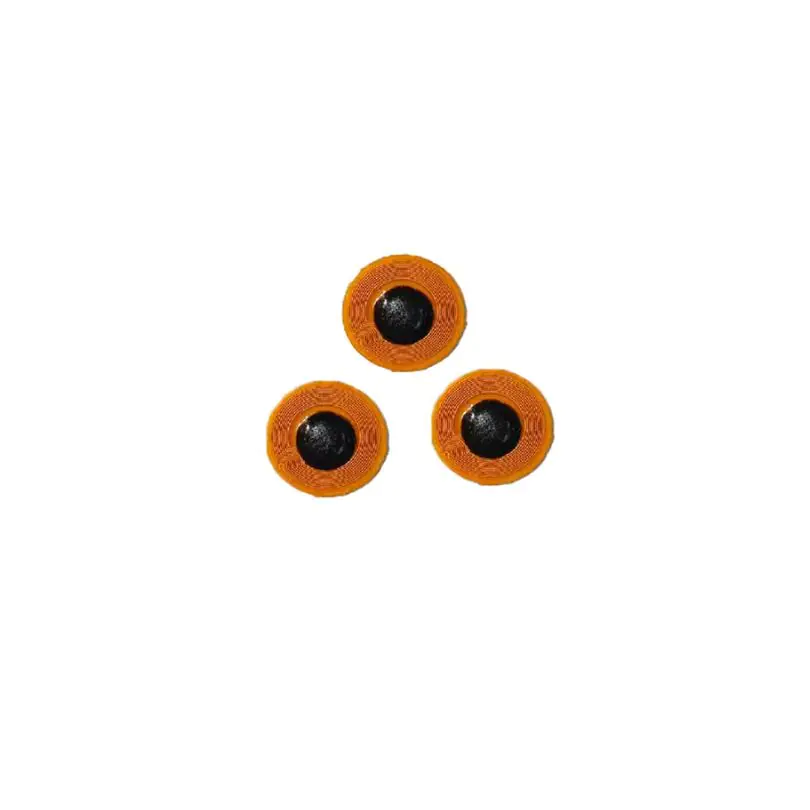

High-Frequency (HF) RFID Tags | No internal power source | Metal/liquid environments | Strong anti-interference, short reading range |

Ultra-High-Frequency (UHF) RFID Tags | No internal power source | Rapid scanning in large-scale inventories | Long reading distance, fast reading speed |

Passive RFID Tags

Passive RFID tags are powered by the signal from the RFID reader, making them cost-effective and long-lasting. These tags are ideal for large-scale inventory management where cost efficiency is a priority.

Active RFID Tags

Active RFID tags come with built-in batteries, enabling them to send signals actively. They are particularly useful in scenarios requiring long reading distances and real-time tracking, such as managing large volumes of cargo in warehouses.

High-Frequency (HF) RFID Tags

Operating in the 13.56 MHz frequency band, HF RFID tags are designed for environments with metal or liquid interference. Their strong anti-interference capability makes them suitable for applications like asset tracking in industrial settings.

Ultra-High-Frequency (UHF) RFID Tags

UHF RFID tags, operating in the 860-960 MHz frequency band, are known for their long reading distances and fast data capture. They are commonly used in retail and logistics industries for large-scale, rapid inventory management.

Industry Applications of RFID Tags

RFID technology is widely used across various industries for inventory management. Below are some notable case studies that highlight the successful implementation of RFID tags:

Retail Industry: Walmart

Walmart, one of the world’s largest retailers, has integrated RFID technology into its inventory management system. By using RFID tags, Walmart can track in-store inventory in real time, reducing the risks of stockouts and overstocking.

Manufacturing Industry: Boeing

Boeing employs RFID technology to enhance its supply chain management. Using Omni-ID’s RFID tags, Boeing can monitor the location and status of parts in real-time, improving production efficiency and reducing costs related to lost or delayed components.

Medical Industry: Kaiser Permanente

Kaiser Permanente utilizes RFID technology to manage its inventory of medical equipment and pharmaceuticals. High-frequency RFID tags help ensure accurate inventory records, reducing the risk of expired or misplaced medications.

FAQs About RFID Tags in Inventory Management

What Advantages Do RFID Tags Offer Over Traditional Barcode Systems?

RFID tags allow for automatic data reading, minimizing manual errors, and support batch scanning with real-time data updates.

What Factors Should Be Considered When Selecting RFID Tags?

When choosing RFID tags, businesses should consider factors such as operating frequency, reading distance, environmental adaptability, and cost.

What Challenges Exist in Implementing RFID Tags?

Challenges include signal interference, high initial investment costs, and ensuring data security during implementation. Proper planning and evaluation are essential to overcoming these obstacles.

Conclusion

RFID technology offers substantial benefits for inventory management, including improved accuracy, visibility, and efficiency. By understanding the various types of RFID tags and their applications, businesses can make informed decisions to optimize their inventory processes and enhance overall operational performance. As industries continue to evolve, the integration of RFID technology will play an increasingly vital role in maintaining a competitive edge in inventory management.

Comments

Hot Products

RFID Laundry Tag Guide 2025: Smarter Tracking, Less Waste, and Real Results

Did you know that smart RFID systems can reduce laundry losses by up to 95%? That’s a game-changer for laundry businesses that lose time and money tracking items manually.

How RFID Tags for Pallet Streamline Tracking in Warehouses

Pallet-level tracking is critical for inventory accuracy, operational efficiency, and real-time visibility in today’s fast-paced logistics and supply chain environments.

Top 5 Types RFID Tag for Warehouse Automation

Warehouse operations are becoming more complex, and manual tracking methods can’t keep up. RFID tags for warehouse automation enable real-time data capture, faster inventory processing, and better traceability.

RFID Smart License Plates Help Hengshui to Track The E-Bikes

As urbanization accelerates and the green travel movement gains momentum, electric bicycles have become vital to daily commuting in Hengshui, Henan Province.

What is A PCB Tag

Learn how innovative tag and RFID solutions transform industries from retail and logistics to healthcare and education.

RFID vs NFC: The Key Differences Between RFID and NFC

This article explores the differences between RFID and NFC, two technologies revolutionizing business operations.

Tags

RELATED BLOGS

RFID Laundry Tag Guide 2025: Smarter Tracking, Less Waste, and Real Results

Did you know that smart RFID systems can reduce laundry losses by up to 95%? That’s a game-changer for laundry businesses that lose time and money tracking items manually.

How RFID Tags for Pallet Streamline Tracking in Warehouses

Pallet-level tracking is critical for inventory accuracy, operational efficiency, and real-time visibility in today’s fast-paced logistics and supply chain environments.

Top 5 Types RFID Tag for Warehouse Automation

Warehouse operations are becoming more complex, and manual tracking methods can’t keep up. RFID tags for warehouse automation enable real-time data capture, faster inventory processing, and better traceability.