What is a passive RFID tag?

Table of Contents

Active vs Passive RFID Tags: A Comprehensive Comparison Guide 2024

This comprehensive guide breaks down the key distinctions, use cases, and helps you make an informed decision for your specific needs. Whether you’re new to RFID technology or looking to upgrade your existing system, this article will provide valuable insights into both types of RFID tags.

What Are RFID Tags and How Do They Work?

RFID tags are electronic devices that use radio frequency waves to communicate with RFID readers. The technology consists of three main components: the tag (transponder), the reader (interrogator), and the antenna. Each type of RFID tag serves different purposes and offers unique capabilities for various applications.Modern RFID systems have revolutionized asset tracking and inventory management across industries. The choice between active and passive RFID tags can significantly impact your system’s performance and cost-effectiveness.

Key Differences Between Active and Passive RFID Tags

Power Source

- Active RFID Tags: Include an internal power source (battery)

- Passive RFID Tags: No power source, powered by reader’s electromagnetic field

- Semi-passive Tags: Hybrid approach with battery for specific functions

Read Range Comparison

| Tag Type | Typical Range | Maximum Range |

|---|---|---|

| Active | 30-100m | Up to 150m |

| Passive | 1-10m | Up to 30m |

| Semi-passive | 15-30m | Up to 100m |

How Do Passive RFID Tags Work?

Passive RFID tags rely on the reader’s electromagnetic field for power. When a passive tag enters a reader’s field, it uses the signal from the reader to power up and transmit data back to the RFID system. These tags are simpler in design and more cost-effective for large-scale deployments.The antenna in passive RFID tags serves dual purposes: capturing power from the incoming signal and sending data back to the reader.

Understanding Active RFID Tag Technology

Active RFID tags continuously transmit signals to an RFID reader using their onboard power source. This independent power supply allows for:

- Longer read range

- Real-time tracking capabilities

- More robust data transmission

- Enhanced processing capabilities

Common Use Cases for Different RFID Tags

Active RFID Applications:

- Large asset tracking

- Vehicle monitoring

- Personnel tracking

- Container tracking

- High-value equipment monitoring

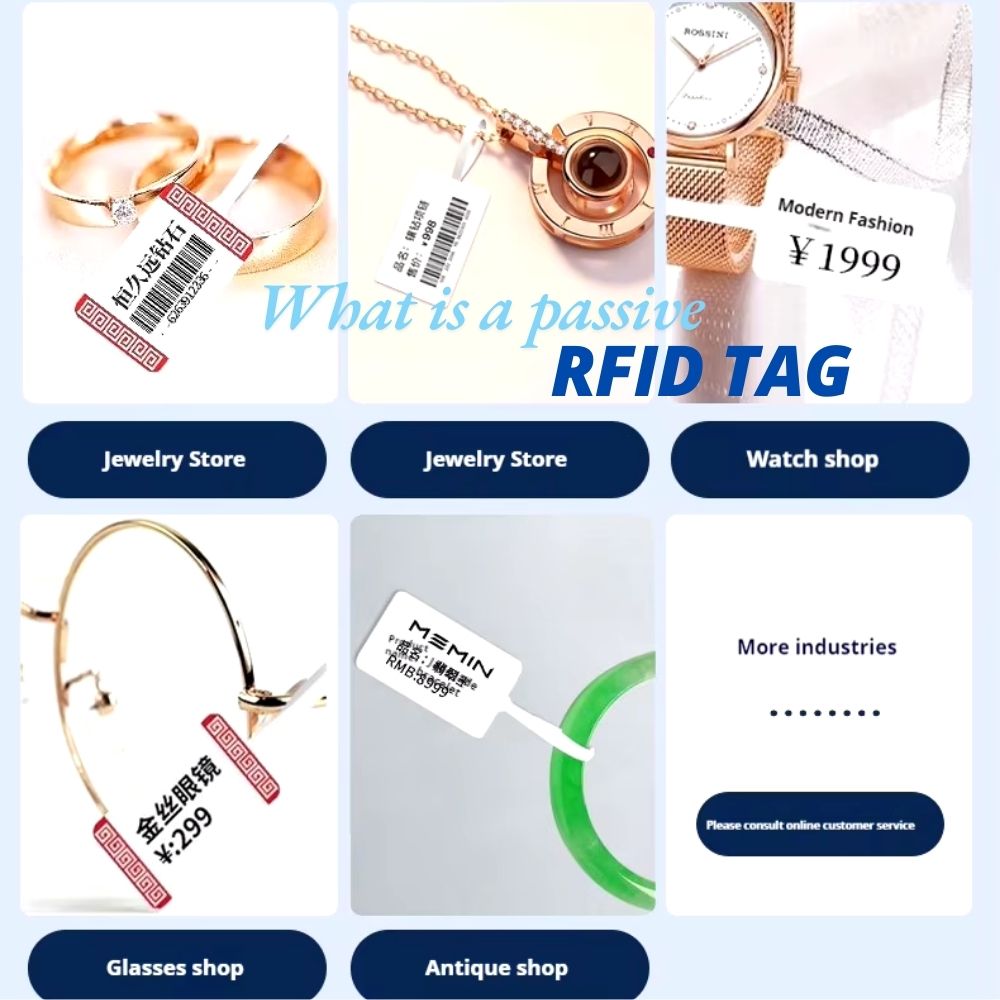

Passive RFID Applications:

- Inventory management

- Access control

- Supply chain tracking

- Retail item tracking

- Document management

Cost Considerations and ROI

Active RFID tags typically cost more than a hundred dollars each, while passive tags can cost as little as a few cents. Consider these factors when calculating ROI:

- Initial investment

- Battery life and replacement

- Infrastructure requirements

- Maintenance costs

- System longevity

Frequently Asked Questions

What is the typical battery life of an active RFID tag?

Active RFID tags usually have a battery life of 3-5 years, depending on the transmission frequency and environmental conditions.

Can passive RFID tags work through metal?

Passive RFID tags typically struggle with metal surfaces, but specialized tags are available for metallic assets.

What's the difference between semi-passive and active RFID tags?

Semi-passive tags use batteries only for powering the microchip, while active tags use batteries for both the microchip and signal transmission.

How do I choose between active and passive RFID systems?

Consider your read range requirements, budget, asset value, and tracking frequency needs when making your decision.

Comments

Hot Products

RFID in Logistics: How to Eliminate RFID Misrouting and RFID Label Failures

RFID in logistics is more than just a tool to speed up processes. It has become a key part of how modern supply chains operate.

What Is RFID Waste Management

Imagine a city where every trash bin speaks — not literally — but through a tiny chip that tells the system when it’s full, when it’s emptied, and where it went. That’s what RFID waste management is doing today.

What are Bolt Seals and their Applications? | Complete Guide

In global trade and logistics, bolt seals play a crucial role in ensuring cargo security and compliance. These small but powerful devices are designed to lock shipping containers, trailers, and cargo doors with a tamper-evident mechanism.

What is an RFID Card Protector? Benefits, Use Cases, and Buying Guide

RFID technology (Radio Frequency Identification) is everywhere: in your credit cards, ID badges, transit passes, hotel room keys, and more. It offers speed and convenience, but it also opens the door to a new kind of digital theft called “skimming.” That’s where an RFID card protector comes in.

RFID Wristbands for Events: Bulk Buying Guide for Organizers

RFID wristbands for events are becoming the go-to solution for organizers who need faster entry, fraud prevention, and cashless payments at concerts, festivals, and sports venues. Unlike paper tickets or QR codes, these smart wristbands use embedded chips to streamline access, secure transactions, and improve the guest experience.

How RFID Tag on Windscreen Improves Vehicle Access Control and Toll Systems

In today’s fast-paced world, vehicle identification needs to be quick, secure, and contactless. An RFID Tag on the Windscreen provides exactly that — a reliable way to manage toll collection, parking, and gated access without stopping vehicles.

Tags

RELATED BLOGS

RFID in Logistics: How to Eliminate RFID Misrouting and RFID Label Failures

RFID in logistics is more than just a tool to speed up processes. It has become a key part of how modern supply chains operate.

What Is RFID Waste Management

Imagine a city where every trash bin speaks — not literally — but through a tiny chip that tells the system when it’s full, when it’s emptied, and where it went. That’s what RFID waste management is doing today.

What are Bolt Seals and their Applications? | Complete Guide

In global trade and logistics, bolt seals play a crucial role in ensuring cargo security and compliance. These small but powerful devices are designed to lock shipping containers, trailers, and cargo doors with a tamper-evident mechanism.