RFID in Logistics: How to Eliminate RFID Misrouting and RFID Label Failures

Table of Contents

Introduction: Why RFID in Logistics Is Now a Risk-Control System

The way shipments are routed, inventory is tracked, and orders are processed all rely on how well your RFID system works. When RFID systems fail, the impact can be huge, affecting everything from delivery times to customer satisfaction.

A common, but often overlooked, issue RFID in logistics is this: old RFID labels that should have been deactivated continue to cause problems. These labels can lead to RFID misrouting and tracking errors, causing chaos in distribution centers.

In this guide, I’ll explain why this happens, how RFID technology works in real life, and how to set up a system that prevents these issues for good.

The Problem: How RFID Misrouting Happens

In a warehouse, when an RFID reader scans a tag, it triggers a routing decision. The system completely trusts the information it reads. There’s no visual check — it’s all about the RFID signal.

Misrouting starts when:

- Old RFID tags are still attached to packages.

- Multiple RFID tags are on one package.

The system reads the wrong RFID tag.

From there, everything downstream is built on incorrect data. This is how RFID tracking errors quietly spread through the entire system.

How RFID Technology Works

RFID (Radio Frequency Identification) doesn’t rely on sight; it works through radio waves. Here’s the basic process:

- The reader sends out RF energy.

- The RFID tag absorbs this energy through its antenna.

- The chip inside the tag responds with a unique ID (known as the EPC or UID).

As long as the antenna is intact, the tag is still active. That’s why scratching out or crossing out a tag doesn’t work. The label can still send out data, leading to misreads and mistakes.

Real-World Impact

Here’s the thing: even a single incorrect RFID read can trigger a chain of problems. Studies show:

- One misread can cause 6 to 12 errors down the line.

- Over 70% of RFID misrouting issues come from leftover or multiple RFID tags.

- Fixing one misrouted shipment costs 8 to 15 times more than preventing it in the first place.

The Ultimate Engineering Framework for RFID in Logistics

Effective RFID in logistics requires system engineering, not training slogans.

Level 1: Physical Control of RFID Tags

An RFID Tag must be electrically disabled:

- Full removal of the antenna

- Cutting the antenna trace

- Or using destructible RFID Tags that break when removed

Only an electrical failure permanently disables an RFID Tag.

Why Damaged Printed-Antenna UHF RFID Tags May Still Be Read

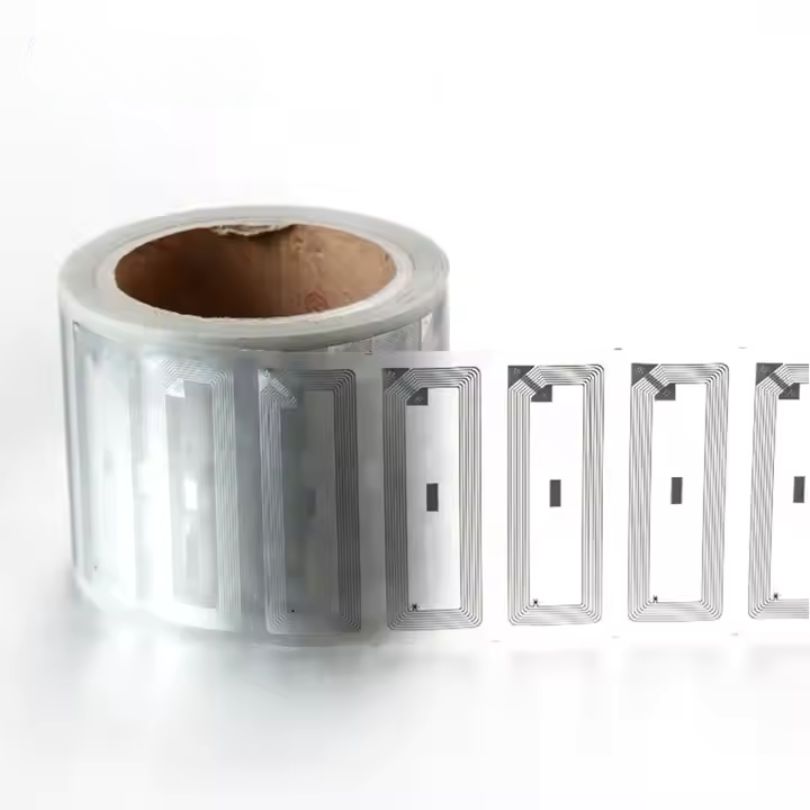

Many RFID logistics operations use printed antenna UHF RFID Tags on paper for cost efficiency.

However, a critical misconception creates serious RFID label problems:

A damaged paper UHF RFID Tag is often not actually dead.

When paper UHF RFID Tags are torn:

- The antenna may crack, but not fully break.

- The circuit remains continuous but inefficient.

- The antenna becomes detuned.

- The break may miss the chip feed point.

- Torn segments can still exchange energy by capacitive coupling.

The result is:

- Shorter read range

- Stronger directionality

- Unstable behavior (sometimes readable, sometimes not)

This unstable behavior significantly increases RFID misrouting risk and RFID tracking errors.

Level 2: Intelligent RFID Tag Architecture

Professional RFID in logistics systems uses process-stage identities.

Each RFID Tag is valid only within:

- A specific logistics phase

- A defined system

- A limited time window

Outside that scope, the EPC is rejected by the system.

Level 3: System-Level RFID Filtering

Advanced RFID warehouse management systems must apply:

- EPC format validation

- RSSI signal filtering

- Process node whitelisting

- Tag aging rules

This prevents wrong tag takeover even when multiple RFID Tags are present.

Level 4: RFID Hygiene Points

An RFID Hygiene Point is a mandatory checkpoint where each package must contain only one valid RFID identity.

Install at:

- Returns processing

- Repack stations

- Cross-system handovers

- Final outbound inspection

Where Tamper Proof NFC tags Fit Into RFID in Logistics

While UHF RFID Tags drive long-range tracking in RFID logistics, tamper proof NFC tags provide the final layer of identity control.

They are deployed at return inspection, repacking, and final verification to ensure old identities are physically destroyed before a new logistics cycle begins.

Unlike paper UHF RFID Tags, tamper proof NFC tags break their antenna at the chip feed point, guaranteeing true electrical failure — no partial circuits, no ghost reads.

This makes tamper proof NFC tags essential risk-control components of modern rfid technology in logistics.

RFID Tag Behaviors After Damage

| Feature | Printed Antenna UHF RFID (Paper) | NFC Destructible RFID Tag |

|---|---|---|

| Damage result | Often still partially readable | Guaranteed electrical failure |

| Post-damage read range | Shorter, unstable | None |

| Read consistency | Unpredictable | Completely inactive |

| RFID misrouting risk | High | Very low |

| Best role | High-volume tracking | Identity destruction & safety control |

Case Study: Cutting Down Misrouting in a High-Volume Operation

A fulfillment center processing 80,000 parcels per day experienced chronic RFID misrouting and RFID tracking errors.

After implementing:

- RFID Hygiene Points

- EPC validation rules

- NFC destructible RFID Tags at returns & repack zones

Results after 90 days: - 92% reduction in RFID misrouting.

- 41% decrease in customer complaints.

- 27% reduction in manual intervention.

Why UHF RFID Tag Selection Still Matters

The UHF RFID Tag remains the backbone of RFID in logistics.

Poor UHF RFID Tag selection causes:

- Missed reads

- Ghost reads

- Inconsistent detection

- Higher RFID tracking errors

Stable antenna design and controlled read range are critical.

FAQs — RFID in Logistics

Why does RFID in logistics cause misrouting even when labels look correct?

Because RFID is radio-based, not visual. The system trusts the RFID Tag completely.

How can I permanently disable an RFID Tag?

By destroying the antenna or using NFC destructible RFID Tags.

What causes most RFID tracking errors?

Leftover RFID Tags, missing RFID Hygiene Points, and weak system filtering.

What is an RFID Hygiene Point?

An RFID Hygiene Point is a checkpoint where packages are verified to contain only one active RFID identity before entering the next logistics stage.

Can one leftover RFID Tag really cause a whole shipment to be misrouted?

Yes. A single incorrect RFID read can redirect the shipment in the system and trigger multiple downstream errors in routing and inventory.

What is the difference between RFID visual damage and electrical failure?

Electrical failure breaks the antenna circuit, which is the only way to disable an RFID Tag permanently.

Why does RFID misrouting happen more often in return and repack areas?

Because returned packages often contain multiple old RFID Tags, the risk of incorrect identification increases.

Are destructible RFID Tags worth the cost?

Yes.They significantly reduce misrouting, manual handling, and return costs, which are far more expensive than the tag itself.

Conclusion: RFID in Logistics Requires Engineering, Not Guesswork

RFID in logistics is a control system.

Without proper design, RFID logistics creates its own failures.

With disciplined architecture, intelligent filtering, RFID Hygiene Points, and NFC destructible RFID Tags, rfid technology in logistics becomes a powerful risk-reduction engine.

If your operation is suffering from RFID misrouting, RFID tracking errors, or RFID label problems, the cause is almost always system design — not staff behavior.

Contact our team to evaluate your RFID logistics architecture and implement proven risk-control solutions using NFC destructible RFID Tags.

Ray Zhou

This article was written by Ray Zhou, an RFID technology expert with more than 10 years of industry experience.

Comments

Hot Products

RFID in Logistics: How to Eliminate RFID Misrouting and RFID Label Failures

RFID in logistics is more than just a tool to speed up processes. It has become a key part of how modern supply chains operate.

What Is RFID Waste Management

Imagine a city where every trash bin speaks — not literally — but through a tiny chip that tells the system when it’s full, when it’s emptied, and where it went. That’s what RFID waste management is doing today.

What are Bolt Seals and their Applications? | Complete Guide

In global trade and logistics, bolt seals play a crucial role in ensuring cargo security and compliance. These small but powerful devices are designed to lock shipping containers, trailers, and cargo doors with a tamper-evident mechanism.

What is an RFID Card Protector? Benefits, Use Cases, and Buying Guide

RFID technology (Radio Frequency Identification) is everywhere: in your credit cards, ID badges, transit passes, hotel room keys, and more. It offers speed and convenience, but it also opens the door to a new kind of digital theft called “skimming.” That’s where an RFID card protector comes in.

RFID Wristbands for Events: Bulk Buying Guide for Organizers

RFID wristbands for events are becoming the go-to solution for organizers who need faster entry, fraud prevention, and cashless payments at concerts, festivals, and sports venues. Unlike paper tickets or QR codes, these smart wristbands use embedded chips to streamline access, secure transactions, and improve the guest experience.

How RFID Tag on Windscreen Improves Vehicle Access Control and Toll Systems

In today’s fast-paced world, vehicle identification needs to be quick, secure, and contactless. An RFID Tag on the Windscreen provides exactly that — a reliable way to manage toll collection, parking, and gated access without stopping vehicles.